|

Before the glassblowing session begins, the pot

furnace or tank furnace must be brought up

to temperature (about 2050-2100°F) from the setting it held overnight (about 1800F to

save fuel.)

(The process

of melting batch or cullet to

get workable glass is discussed here)

The glory hole for reheating

must be brought up to temperature (~2200-2300F) as well as the controlled

cooling annealers

(~900F), preheating color oven, pipe heater,

and garage. Depending on equipment design,

these steps take about an hour. During this time, the artist is

normally setting up the preheating of color bar and laying out

stringer, frit,

and powder (linked below as

discussed), arranging tools, and pulling the previous day's or

afternoon's work from the annealers. Pipes and punties are

arranged in the pipe warmer for use during the

session. Water is put in holding buckets and crack off bins/buckets

, if used. If hand torches are used,

they will be lighted or set out.

Most furnace glassworkers use a team approach for making glass with at least

one assistant who may be a partner alternating on the bench or a less

experienced glass blower who gets some blowing time during the day. A

minority of furnace workers work alone (as I do) and some pieces are more

difficult and some impossible when alone and different techniques are used to

compensate. Large pieces and production shops often involve teams of 3, 4,

5 or more working together. These additional people may take the partially

worked piece back for reheating, giving the gaffer a break; may make added bits

like handles; may bring color bits to a nearly molten state for application; may

prepare and hold the punty as mentioned below; and may suit up to carry the

finished but still hot piece to the annealer. [2010-12-22 add.]

The creation of an object commonly begins by making or taking out a drawing

so that all involved know the piece to be made and the steps involved. In a

production situation there may be metal templates or calipers to gauge heights,

diameters and shapes. Building the object begins by taking the pipe from the pipe heater

where it has been pre-heating. A pipe that is cold will simply push a hole in

the molten glass instead of gathering or the glass will chill around the small

hole, preventing blowing from happening. Upon opening the

door to the furnace, the pipe is tipped at an

angle into the pool of glass and moved across while turning the pipe and pulling

a gather of glass. If left in too long, the pipe get so hot the glass flows off.

Pulling the pipe, the door must be closed and the pipe turned to maintain an

even shape of glass. The glass worker most commonly goes to a

marver to roll the gather into a blunt cone against

the flat surface. Using breath, a small bubble is started in the

center of the glass and enlarged to the size the worker desires.

(The primary glassworker is called a gaffer from an old word for

grandfather, but I am not using the term here because when a team

is working glass, any of the workers, not just the gaffer, may

marver and otherwise work the glass.) If the pipe end is too cold, the

glass will stiffen immediately and the bubble won't start. If it is too

hot, only a thin shell of glass will be picked up, wasting time. The exact

temperature of the glass in the furnace will depend on the preferences of the

gaffer and the need to gather glass in thin or thick layers as higher

temperature glass is thinner. [rev 2009-08-23]

When the glob glass, called a

parison, is shaped,

it is allowed to cool further. This both assures that the shape

will not collapse when more molten glass is gathered around it and

increases the amount of glass that can be picked up in the second

gather. A pipe usually has a small hole in the end with a thick rim around

it. It is possible to blow glass with an open pipe (straight wall thickness) but

it does not support the piece well. When the glob glass, called a

parison, is shaped,

it is allowed to cool further. This both assures that the shape

will not collapse when more molten glass is gathered around it and

increases the amount of glass that can be picked up in the second

gather. A pipe usually has a small hole in the end with a thick rim around

it. It is possible to blow glass with an open pipe (straight wall thickness) but

it does not support the piece well.

Many pieces start with an additional step. The worker heats

the end of the pipe, but rather than gathering the glass, a chunk

of color is picked up as a short cylinder preheated in a color kiln. The old skin of glass on the pipe is usually

enough to stick the pickup. The color is softened in the glory

hole and marvered to shape as described above. As other glass is

gathered over it, the color forms the inner lining of the piece

and colors the whole piece. When desired, two or more chunks of

glass may be worked this way to form layers. If the color chunk

contains lead or other heavy metals and the object will hold food

or drink, the color may be picked up after the first gather and smoothed over it so the

inside of the piece is a thin layer of clear with color over it

and more clear (later gathers) over that. Some studios melt

colored glass which may be used for the first gather or for

adding details later but most studios melt a large pot/tank of

clear and use solid color.

After the second gather, the worker normally has enough glass

that a change of techniques is required, although returning to

the marver to shape the second and third gather or even the whole piece

is used by some workers. Most workers will go to the bench and use wooden blocks or a pad of newspaper

to block or shape the glass. A team member may blow while the gaffer turns to

shape the glass against the block; a solo worker may use an extension air tube. If further gathers are to be made,

the object of blocking is to control the shape of the piece

including the thickness of the glass. Again the piece will be

worked and cooled to stiffen the shape to permit more glass to be

gathered. During gathering, steps may be taken that are part of

the design, where the design calls for color within the glass.

This may include threading,

picking up cane, or adding bubbles. The bubble inside the glass

may be enlarged during the gathering. The glass may be

selectively chilled (on the sides or the bottom) to cause more

glass to be gathered there or to encourage the bubble to move

into the hotter area. Following gathering, the worker may drain excess glass just gathered into

a water filled bucket to form a thinner smoother layer around the

piece.

At some point enough glass has been gathered to make the piece.

The next step is normally to use bladed jacks

to narrow a neck on the piece near the end of the pipe. This is

the line where the piece will separate from the pipe. The piece

is taken back to the glory hole for reheating.

The glory hole is usually maintained at a temperature higher than

the furnace, so it reheats the glass quickly. The heat transfers

from the walls and air of the glory hole, heating it all around,

supplying more heat per second than a torch would. Because the

glass near the pipe is behind the rest of the piece (in the

shadow of the heat) it may take several reheats to jack the line

properly, so other work may be done as the jacking proceeds. The gaffer must

work to keep the glass centered in line with the pipe.

During this stage, the worker may use other jacks, other

blocks, the newspaper, the paddles, and the

marver to form the piece. A co-worker may kneel at the end of the

pipe on the bench and blow in the pipe as it rolls (a fun task),

blowing while the gaffer applies shaping pressure with the paper,

etc. (A gaffer, especially working alone, may also use an air hose over the pipe mouth piece to apply air

pressure while the pipe is on the bench, using breath or low

pressure compressed air.) Air or pads may also be used to

selectively cool the glass so that when it is reheated, other parts will begin

at a higher temperature and get even warmer and softer than the chill parts.

Gravity and centrifugal force may be used. If the pipe is

pointed down while turning, the piece will tend to lengthen;

while pointing it up will shorten. Some caution is required when pointing

up as hot bits of metal corrosion may be in the pipe which must be cleaned out. If the pipe is swung back and

forth or (spectacularly in demonstrations) swung completely

overhead the piece will stretch and thin, doing more so near the

neck (because more glass is pulling from further out) or where

the glass is hottest.

The

worker is mostly working on the lower half of the piece. Steps

the worker might take include using an optic or

other mold to impress a pattern or shape on

the glass and using various techniques to add color including threading and rolling the piece in frit or powder

which may be in a scoop shape or laid out on the marver. The

worker is mostly working on the lower half of the piece. Steps

the worker might take include using an optic or

other mold to impress a pattern or shape on

the glass and using various techniques to add color including threading and rolling the piece in frit or powder

which may be in a scoop shape or laid out on the marver.

The last step before taking the piece off the pipe is

finishing the bottom where the punty will be attached. Normally

this involves flattening the bottom and adding any foot or feet

desired. It may also involve adding a pad of glass (cookie) to keep the bottom from

breaking out when the piece is puntied.

If glass is being produced as quickly as possible and a

polished rim is not important, all the following steps are

ignored and the piece is cracked free and taken to the annealer

immediately. The top of the cooled piece is sawn square and ground to

final shape. Low cost vases and garden decorations with added

caps may have this shortcut used as well as pieces blown into metal forms.

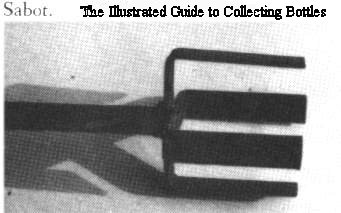

The

most critical step in working the glass is getting the piece off

the pipe and onto the punty. The problems are

rooted in the desire later on to remove the punty with little

scarring and as little cold working as

possible. The artist or assistant gathers a small amount of glass

on the punty and quickly marvers it to shape, usually a blunt

cone. The glass is then usually touched to some surface to chill

it and pattern its surface. The goal is to make a good enough but

not TOO good connection to the glass. If the connection is not

good enough the piece will fall off the punty. The first and

perhaps most likely time for this to occur is when the pipe is

rapped to crack it free. If the connection is too good, it may crack the bottom

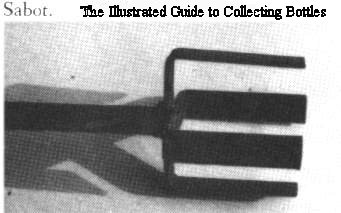

of the piece at the end of the session. In production situations, it is

common to have a mechanical punty (a gimmick or

sabot) that encloses or grips the piece to avoid the risks

and time of the hot punty process.) The

most critical step in working the glass is getting the piece off

the pipe and onto the punty. The problems are

rooted in the desire later on to remove the punty with little

scarring and as little cold working as

possible. The artist or assistant gathers a small amount of glass

on the punty and quickly marvers it to shape, usually a blunt

cone. The glass is then usually touched to some surface to chill

it and pattern its surface. The goal is to make a good enough but

not TOO good connection to the glass. If the connection is not

good enough the piece will fall off the punty. The first and

perhaps most likely time for this to occur is when the pipe is

rapped to crack it free. If the connection is too good, it may crack the bottom

of the piece at the end of the session. In production situations, it is

common to have a mechanical punty (a gimmick or

sabot) that encloses or grips the piece to avoid the risks

and time of the hot punty process.)

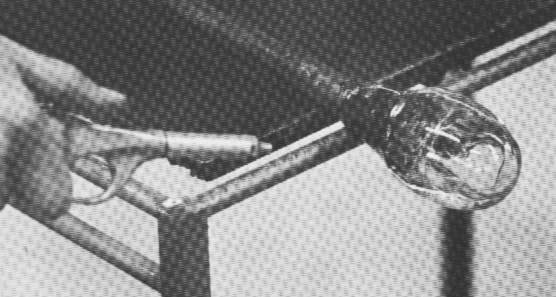

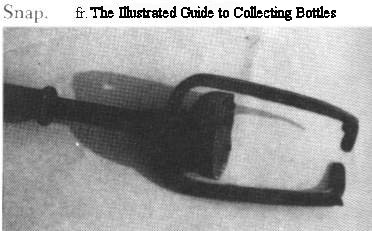

If the worker has successfully jacked the piece and properly

tempered and attached the punty, when the pipe is rapped with a

hard tool, the piece parts cleanly and without much shock. Many glass workers

put water on the joint with tweezers to cool and shock it. If the

punty glass is too hot, there may be a bit of frantic turning and

twisting of the punty to keep the piece centered and in place.

Most commonly, the gaffer places the punty tip with shears while

an assistant holds the punty level. The gaffer then raps the pipe

when everything seems right and the assistant catches weight of

the piece and goes immediately to the glory hole. (If the piece

has not been properly puntied, or the neck not properly narrowed

or chilled, rapping on the pipe may result in both ends of the

piece breaking free, resulting in a "floor model" - a

broken piece.)

Commonly, in a small studio, the gaffer follows the assistant

and takes the punty while handing the pipe to the assistant who

puts it in the crack off bin while the gaffer turns the piece in

the glory hole. In a larger operation, a team member other than

the gaffer will reheat. Notice that the end of the piece going in

the glory hole has been determinedly chilled for the past several

minutes so it will crack free and now it must be heated up to

soft working temperature while keeping the rest of the piece

tepid or at least firm.. It is possible that the end has gotten

so cold that it cracks in error, so it should be eased into the

glory hole.

When the piece is pulled from the glory hole, it is time to

work on the rim and upper body of the piece. If the piece has

been necked severely, the inner hole may be too small and it must

be worked open with pick or tweezers.

In more ordinary work, the jacks are used with the blades

parallel to form a broader working surface to turn the rim open.

Many glass workers next pick up duckbill shears to

trim away excess glass and shape the lip. Trimming is normally

done with very soft glass and at the bottom as the piece is

turned horizontally, so the scrap falls toward the floor and does not mar the

piece. On goblets and thin pieces, the goal may be to remove the

thicker or uneven glass at the jack point. On a pitcher, the goal

may be to provide the profile that will yield a projecting lip.

The cut glass normally falls on a metal tray provided for the

purpose.

Frequently these days, a lip wrap of

contrasting color is added. Continuing work shapes the top of the

piece, perhaps the size being gauged to match a lid previously

made or to allow for a stopper. With an assistant or alone,

additional bits are added for decoration and for handles. During

this time, the worker will return the piece to the glory hole to

keep it from cracking. A torch may be used to

apply heat to the bottom of the piece and/or the punty glass when

trying to heat this area in the glory hole would soften the rest

of the piece too much. A torch may also be used to heat a spot

where a bit or garaged section is to be attached. A torch may be used to

apply heat to the bottom of the piece and/or the punty glass when

trying to heat this area in the glory hole would soften the rest

of the piece too much. A torch may also be used to heat a spot

where a bit or garaged section is to be attached.

When the piece is complete, the next critical step is to

remove it from the punty, which requires that the punty glass be

removed without taking a chunk out the bottom of the piece. If

the punty was applied properly, removing the piece is merely a

matter of chilling the join, usually with a thin knife edge. If

the worker has any doubts about the separation, a number of

tricks/techniques exist to encourage the break to occur in the

punty glass and not in the piece. They must be applied quickly as

the glass is cooling rapidly and unevenly.

The piece is normally removed with a sharp rap to the punty.

What happens to the piece depends on the worker and the piece.

Some pieces can be placed in the annealer by holding the punty

vertically, lowering the piece to a fraction of an inch above the

annealer floor, and rapping. Gloves are

available which will withstand the 800-1000°F heat for a short

time. The worker may hold the piece over a padded drop table and

crack off onto that and then use gloves to move the piece into

the annealer while positioning it as desired. With an assistant,

the gloves can be used to catch the piece (usually above the

crack off table for insurance) at the rap and carry it to the

annealer. With large pieces of glass, the assistant will be

garbed in full silver fire fighting reflective gear. Handling the

piece permits the option of setting it on its bottom or side.

With the piece in the annealer, it is likely that members of

the team and any audience will applaud the success, especially if

it is a large, tricky piece. Water, etc., is drunk, a snack eaten. The various tools and pipes are

arranged for working the next piece and it begins again. The

piece will soak in the annealer for an hour or more (often to the

end of the day) and then will be annealed (cooled

slowly) so the glass is as free of stress as possible. For

ordinary art glass pieces, the temperature is reduced from about 900°F

to about 600°F over 6-8 hours in a controlled way and then

allowed to cool to near room temperature over 3-4 hours or more. Thicker

pieces including castings may require days for proper cooling.

Depending on the time taken for the piece, the production nature of the shop,

etc., the people involved may take a break, drink fluids, etc., before

continuing the piece. In a factory, the team works for a couple of hours,

making a piece every few minutes, before breaking, some people sitting all the

time, others carrying the glass. In a production studio, the gaffer may

work at the glory hole or remain seated.

At the end of the session, the glory hole is turned off, the furnace turned

down or recharged, the annealer is set to begin the cooling process, water is

thrown out, tools picked up or lined up, the floor swept, and trash thrown out,

ready for the next session.

Kile Glassworks Renaissance style

|

|

- A

- Air, Natural Air

- Most glass workers use air from the mouth to gently form glass on the

pipe and after. A common sight is an assistant kneeling by the bench moving

with the end of the pipe mouthpiece blowing while the gaffer shapes the

piece. Solo workers use a blowpipe hose extension,

where surgical tubing (a very soft light amber color) is used with an elbow

swivel that allows the pipe to rotate when the hose is attached. Besides the

hose, an adaptor is needed to fit over the pipe mouth piece. I made mine

from short pieces of clear soft vinyl tubing, which I forced inside each

other to change from the small tubing on the swivel to the large diameter of

the pipe. The puffer is often natural air. 2004-07-26

- Air, Compressed

- Since high pressure (120 psi) air is useful for running tools and sand

blasting, many studios have compressed air at the bench where it is usually

very low pressure (5 psi or less). The two most common uses are

cooling selectively and with the puffer. Many shops have doors operated by

compressed air cylinders. Created with a central or local

air compressor. 2004-07-26

- Air Gun or Nozzle

- A tool with a trigger for releasing moderate to large amounts of air

which is placed on a compressed air hose convenient for cooling glass

selectively. (right) 2005-08-21

- Air Compressor and Air Hose

- A motor driven device using pistons, diaphragms, or rotary vane pumps to

increase the pressure of atmospheric air so that it can be stored and

distributed to do work or provide a blast of air. Usually electric in

shops. Commonly the pump unit is mounted on the storage tank which may

be on wheels or a larger upright cylinder. Small compressors without

tanks are available, usually for painting. Distribution can be by

reinforced rubber hoses or metal piping. PVC pipe is strongly

discouraged for this use as it breaks with time and fires across the shop.

Many shops have quick connect fittings located above head height at each

work station.

Air driven, or pneumatic, tools are widely available for automobile work and

include low and high speed grinding, hammer scaling and cutting bits, socket

drivers, etc. The tools are much lighter than electric (no metal

windings inside.) Some use a lot of air and require bigger compressors

and tanks than many shops have. Tools are high pressure devices,

usually 125 psi.

- Annealer

- Controlled temperature oven, usually electric in art glass studios, for

cooling glass at a controlled rate to relieve strain that

will break glass cooled quickly. Usually built by worker

as volume is needed and temperature range is relatively

low (900-500.) Needs controller. See lehr, fire

brick and ceramic board, fiber &

blanket ANNEALER.HTM

- B

- Batch

- A mixture of chemicals, mostly sand, to be melted to make glass. (see cullet, BATCH.HTM) Batch can

be mixed by the worker or bought. Today the most commonly

used bought batch is from Spruce Pine Batch Co.

although several other companies have appeared on the west coast: East Bay

Batch, Gaffer. Mixing batch requires care as many ingredients are poisonous

or lung damaging. Cooking batch requires higher temperatures than melting

cullet and takes more total energy.

- Batch Trough

- See Trough

- Battledore

- a wooden paddle used to flatten portions of a bottle as

it is being hand blown. IGCB

- Bee's Wax

- Used to lubricate jacks and other tools. From fabric

stores or use a candle. Carnauba wax is harder. Lubricant

is also called mud and mixes for making it work are

legendary in the industry.

- Bell Kiln

- Industry term for a glass fusing kiln where the part that opens is a box

facing down (like a bell hangs) over a flat surface that may roll to one

side, giving complete access to the work surface while retaining heat in a

way that a lid or a door does not. The box is usually counterweight

loaded so it rises and drops smoothly.

www.greatkilns.com has one that is 4x8 feet. 2007-03-20

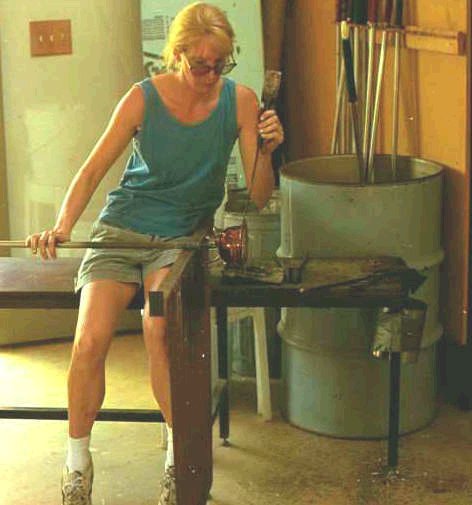

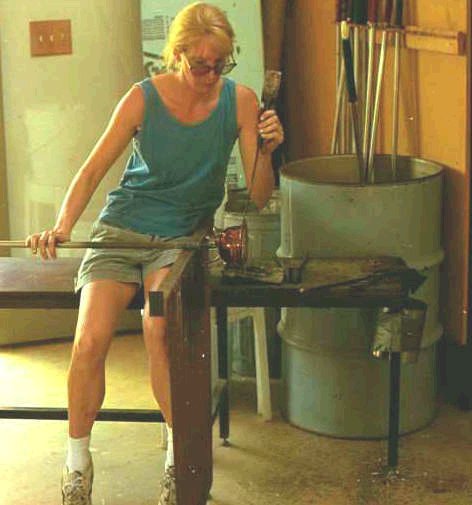

- Bench

-

A glass worker's bench is most commonly a steel framed

long armed chair with a wooden seat that extends beyond

the arms on both sides. Below the arms are metal shields

to protect the legs of the worker from the heat of the

glass. The pipe or punty is placed on the arms and rolled

out and back to keep the glass in a smooth round shape

while working it. On the extended seat [or on a small table the same

height] are placed metal

tools, which may also hang on nails driven in the edge,

and behind the seat are often buckets of water holding

blocks and wooden tools. Since sliding tools

must be waxed (jacks) and gripping tools must not (tweezers,

shears), the waxed tools are placed tips to one edge, the

unwaxed to the other. 2004-07-26 A glass worker's bench is most commonly a steel framed

long armed chair with a wooden seat that extends beyond

the arms on both sides. Below the arms are metal shields

to protect the legs of the worker from the heat of the

glass. The pipe or punty is placed on the arms and rolled

out and back to keep the glass in a smooth round shape

while working it. On the extended seat [or on a small table the same

height] are placed metal

tools, which may also hang on nails driven in the edge,

and behind the seat are often buckets of water holding

blocks and wooden tools. Since sliding tools

must be waxed (jacks) and gripping tools must not (tweezers,

shears), the waxed tools are placed tips to one edge, the

unwaxed to the other. 2004-07-26

-

- A bench is a personal choice and may be built from wood

with steel rails or may be built with sloping arms. Having a bad

back, I stand all the time rather than getting up and down, so I use

one that I stand before

with the arms at waist level and the tools underneath the

arms I also find it easier to get

around the end of pieces and place the punty. Some

workers omit the bench and its arms and work glass on

ball bearing rollers.

Marty Johnson prefers a bench with a

higher and angled seat so she can get on and off it quickly, her heels do

not touch the floor when she is seated. 2003-11-14

More benches

- Bit Iron

- See Iron

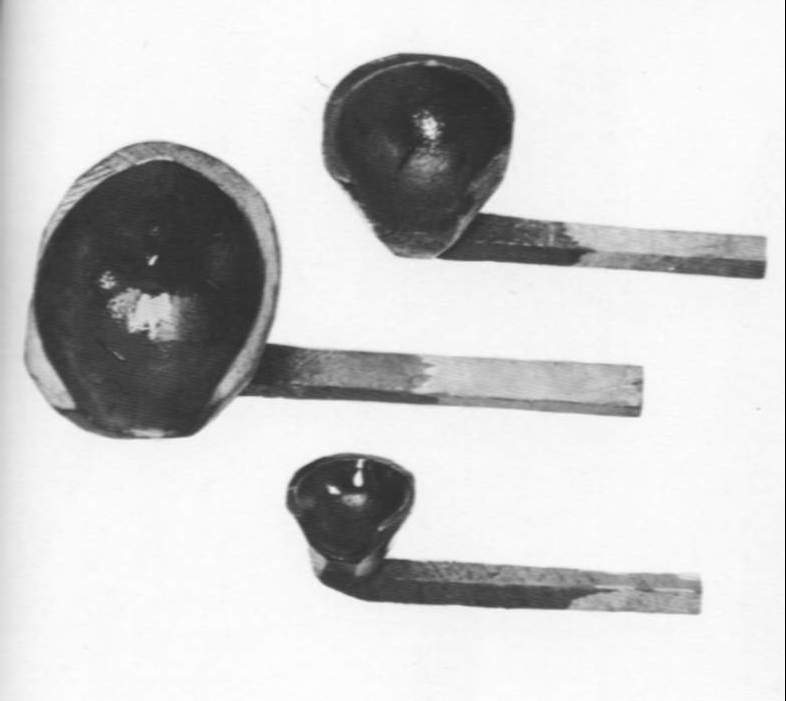

- Blocks

-

Blocks are chunks of fruit wood,

most commonly cherry but also pear and apple, which are

carved to a shape useful in forming glass and then soaked

in water until waterlogged. The steam from the water and

the carbon that forms on the surface makes a durable tool to produce

smooth glass.

Usually will crack if allowed to dry out therefore kept in water or in

plastic bag when traveling. Wooden rods and

paddles are also used the same way. Walter Evans makes blocks for

many studios. OLY ** Image at

right from Harvey Littleton's

book Blocks are chunks of fruit wood,

most commonly cherry but also pear and apple, which are

carved to a shape useful in forming glass and then soaked

in water until waterlogged. The steam from the water and

the carbon that forms on the surface makes a durable tool to produce

smooth glass.

Usually will crack if allowed to dry out therefore kept in water or in

plastic bag when traveling. Wooden rods and

paddles are also used the same way. Walter Evans makes blocks for

many studios. OLY ** Image at

right from Harvey Littleton's

book

- "a wooden dipper-like device cut out on one side and used

during free blowing to give symmetric form to a bottle

in its early stages". IGCB

Paper & Wood

Blocks in use. 2003-11-22

- Blow-back mold

- a full-height mold with a bulb-like formation cut into

the neck of the mold to facilitate severing the completed

bottle from the blowpipe. IGCB

- Blowpipe

- see Pipe

- Blowpipe Hose Extension

- The extension slides over the mouthpiece with a 90 degree

swivel connector attached to a 6 foot piece of latex

tubing that is equipped with a mouthpiece. The use of the

extension will enable you to work a piece at the bench or

glory hole without bringing the pipe to your mouth. The

thin tubing also makes clear how little pressure is

needed for blowing properly heated glass. SIWS Blowpipe

Hose Extension (0.5, 0.625, 0.75, or 1.0 inch) $25 Wale

Apparatus, basic mech.+vinyl tubing

- Bucket

-

Most

studios have a number of buckets around, with or without water in them.

There are four in the image at right, two black ones on roll around stands

holding blocks, one stainless bucket further back and one just peeking past

the corner of the bench seat. These hold the wet tools, wood here,

including a paddle sticking up at the left edge of the photo and the paper

folded over the edge in the middle. 2003-11-22. Crackoff

Buckets Most

studios have a number of buckets around, with or without water in them.

There are four in the image at right, two black ones on roll around stands

holding blocks, one stainless bucket further back and one just peeking past

the corner of the bench seat. These hold the wet tools, wood here,

including a paddle sticking up at the left edge of the photo and the paper

folded over the edge in the middle. 2003-11-22. Crackoff

Buckets

- Burner, Burner Head

- Most furnaces and almost all glory holes are heated with

natural gas or propane driven through a burner head

backed up by plumbing that may be more or less

complicated and include safety features. See BURNER.HTM The burner head is a

matter of commercial contention and may be an open pipe,

a ceramic construction or a similar metal construction. A

head with many holes is designed to be quieter and offer

a greater range of turn up and turn down. A ceramic head

is designed to keep iron bits out of the glass. See Ribbon Burner

A B C D E F G H I J K L M N O P Q R S T U V W X Y Z

- C

Calipers

- A divider or compass like

tool of two arms off a pivot but commonly with curved arms that hook in or

out and primarily used for measurement or comparison. Outward curving

arms are used for inside measurements while inward are used for outside.

When used for measurement, the distance across the tips is put against a

scale. When used for comparison, an existing object is matched to the

new one. Image Lid Calipers 2008-05-20

- Cane Marver

- A marver plate with grooves for

spacing cane evenly to pickup on hot glass. Hard to make

without a metal milling machine, usually bought: Steinert

$60 Aluminum, $95 iron for heating.

- Car Kiln

- More often seen in pottery work although casting places may use it, one

end and the bottom are on wheels (the car) and the unit rolls into the other

four sides forming a box, with a channel of sand to seal the bottom edge.

Allows complete access to bulky stuff while not trying to move the

insulating box (and burners in the case of pottery.) Kiln,

Bell Kiln 2007-03-20

- Casting Ladle

- The casting ladle is made of high grade cast iron and is

designed to be welded to a handle made of 1"

schedule 40 pipe. The ladle is 6 inches in diameter and

will hold up to 7.5 pounds of glass. SIWS - Casting Ladle

$96 A smaller ladle can be made welding a dome cap to

steel tube. see Gathering Ball OLY

- Ceramic fiber blanket, board & paper

- Modern industrial high temperature insulation to replace

much more dangerous asbestos. Available in several forms

and several temperature ranges. Blanket is usually sold

in 100 "board foot" (which is 1 foot by 1 foot

by 1 inch) rolls, so the price given is probably for 1"

thick. The first roll I bought was 48" wide, 2"

thick, and only 12.5 feet long. For the National product,

I have paid well under $100 a roll according to my skimpy

records.. For annealers and most kilns, the lowest

density and the lowest temp rating is all that is needed

and this makes for lower cost. Refractory

- Chair

- Alternate name, historically, for a bench

- where the gaffer sits.

- Clamp

- Alternate holding technique for partially worked glass

GL5K Gimmick,

Sabot

- Clay Pot

- See Pot

- Cold Working

- The general name for sandblasting, grinding and polishing

the glass. While many artists use the procedures of cold

working as part of their artistic creation, most would

prefer to avoid the labor intensive process of grinding

off punty marks and polishing the result. Glass must

always be worked wet, otherwise heat builds up rapidly

and damages the tools and causes cracking in the glass. Grinder, Polisher,

Another page

- Color bars

- Glassblowers using moderate amounts of color in their

glass buy bars of concentrated colored glass about 1"

in diameter and a foot long. This is cut in smaller

chunks and melted, crushed or pulled. Sold by the kilo

for a full bar, cost is effectively $1-3 per inch ($17-48

per kilo.) Those using more color tend to melt their own

to reduce cost and control color values. OLY Color Page

- Color crusher

- Usually a heavy-walled steel pipe with a close fitting

thick steel disk with a handle. Chunks of glass are put

in the tube, the disk placed on top and the handle

pounded with a hammer or just used like a mortar.

Produces dust or small chunks (frit.) A great tool for

making your own glass powders. SIWS - Crusher $80

- Color cutter

- To get color bar into usable sizes, a cold chisel and

hammer will work, often scattering expensive sharp pieces.

A commercial cutter is a guillotine like frame with a

holder for the glass that tries to keep things under

control. Home built in a variety of designs.

- Color oven or kiln

- Any small kiln (or corner of the annealer) used for

preheating chunks of color bars to allow pickup without

cracking. Copper enameling supplier or build, needs very

simple temperature control. Usually has a blackboard near

it to plot layout of various colors which may look

identical.

- Compass

- A tool with two straight arms from a pivot, used today with a marker on

one arm for marking out a circle, but historically in the manner we now use

a divider. 2008-05-20 Image

- Compressor

- See Air Compressor

- Cone

- Pointed tapered tool (cone shaped) Typically 7" long, 3" dia., with handle, Paoli

$30. Wood or graphite, for opening glass shapes and

providing a variable sized round tool for working the

glass.

- Contactor

- A relay-like device used as a noisy power controller or as a safety

cutoff because of leakage through SCR's.

Contactor

- Controller

- When glass has to be held at a specific temperature or

ramped slowly from one temperature to another, some kind

of controller is used. These

days it is usually digital, but mechanical and analog

solid state controllers have been built. Controllers are

available as small boxes under $200 that will ramp and

hold and as more complicated systems that will control up

to 5 or 8 units. Most continuously used studios will have

the furnace under a control along with at least two

annealers and a color oven. Some may have additional

annealers and perhaps small units used as garages for

parking hot glass.

- Cooler

- See Pipe Cooler

- Copa

- "Tool for shaping wraps into round and half round."

Jim

Moore tool Handled tool with a long U-shaped channel that

tapers narrower toward the end.

Another Source

- Cork dust

- is used on metal molds to give a carbon surface. Adhered with

baked linseed oil or special paste sold for the purpose. see below.

- Cork Paddles

- Soft way to massage hot glass for flattening or indenting

sides of blown piece. Unlike most thin paddles, these

have thick round or oval pads of cork and I would be

tempted to call them cord pads if the sellers did not

label them otherwise. CGS $70

to $90 Site

link Or per suggestion on CraftWeb - Alexander Adams - "Next

time you need to make cork paddles or need cork dust, buy a 24" x 12" x 4"

cork slab from McMaster-Carr. In the index it

is listed as Cork Insulation and the item number is #9354K44. It costs about

$18.52 not including shipping. Run these through a clean table saw to make

the cork paddles. Depending on how many cuts you make on the table saw, you

will make plenty of cork dust. If you're picky, you may want to sieve out the

dust that is too big. If your crafty, you can make extra paddles to sell on

E-Bay. Banister Rail, Plywood, Deck Screws and Gorilla Glue are the only

other supplies you will need." 2003-08-07 used with permission An

alternative is

Yoga Cork $9.95 - 9 x 5.5 x 3.5 inch to make two. 2005-04-27

- Cowl Board

- "A wooden face mask used by the furnace tender to protect him from the

intense heat." Collectors Encycl.of

Am.Art.Glass p.225 [MF: In factories, fixed shields used in art

studios.] 2008-05-20

- Crack off table

- See Drop Off Table 2004-07-13

- Crack off bin/bucket

- At the end of each use of pipes and punties there is

usually a collar of glass around the end. This glass will normally

break and shatter off as it cools, perhaps fired with enough

force to hurt people. Therefore the tools are left in

metal (heat proof) buckets or dry bins that capture the

glass. Normally punties have less glass and are placed in

water filled buckets (stainless steel food service

buckets are especially nice). If a pipe is placed in

water without sealing the end, the steam inside almost

instantly makes the pipe too hot to hold, so pipes are

put in steel barrels or flat bins. All crack off catchers

are also used to dump mistakes, broken pieces and scrap

glass. For larger containers a barrel is commonly used.

Often clear glass is separated from colored for reuse.

Stainless steel buckets are very nice, but expensive ($70-85);

stainless steel soup pots are thinner and much less

expensive ($6-12)

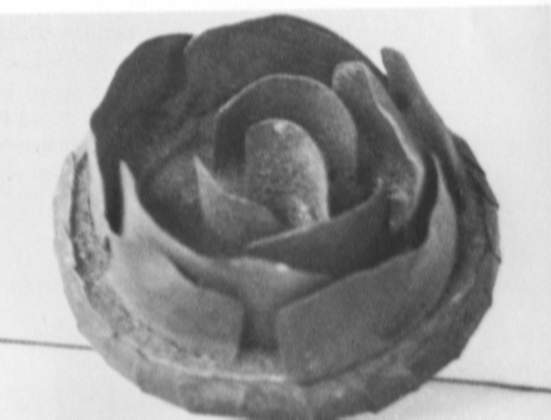

- Crimp

- 1. A tweezer like tool with metal pads on the ends that have a pattern.

When hot glass is squeezed between the pads, the pattern is impressed.

A leaf crimp is perhaps the most common, but ribs, circles, shells, etc. are

available. MOORE 2003-06-22

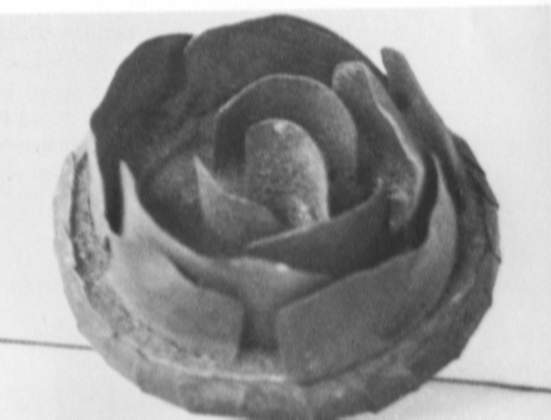

2. A special tool for making Millville rose type

paperweights, it provides the shape of the petals. Color

is picked up on the bottom of clear, heated, and the

crimp is shoved through the color. After the tool is

removed, the base is jacked to taper the rose bottom and

remove the source color, the shape then being puntied at

the base and further encased. If two layers of color are

provided, the tips of the petals shade from one to the

other - pink to red, white to yellow. Crimps are usually

hand made and reworked by the gaffer. Brass is soldered,

the solder protected by plaster of Paris. Thin brass will

melt. [Description and use compiled from several sources,

including GGNJ, Corning Museum Rakow Library notes, and

personal experiments crimp.htm.] the bottom of clear, heated, and the

crimp is shoved through the color. After the tool is

removed, the base is jacked to taper the rose bottom and

remove the source color, the shape then being puntied at

the base and further encased. If two layers of color are

provided, the tips of the petals shade from one to the

other - pink to red, white to yellow. Crimps are usually

hand made and reworked by the gaffer. Brass is soldered,

the solder protected by plaster of Paris. Thin brass will

melt. [Description and use compiled from several sources,

including GGNJ, Corning Museum Rakow Library notes, and

personal experiments crimp.htm.]

3. Crimper "A wooden form that is used to give a bowl or pitcher a crimped

rim." Collectors Encycl.of Am.Art.Glass

p.225

- Cullet

- Broken glass, which melts easier than batch.

Can be remains of previous work, bottles, or purchased.

The latter two may need chemical additions to make more

workable. Available from Gabbert Cullet

and other sources. More here

- Cutter, Color

- An ongoing problem for blowers is cutting the color rods, which are

usually about 1" in diameter and are often used in chunks about an inch

long. They are very hard and very brittle and some of the methods used

scatter color chips far and wide. Guillotine arrangements, cold chisels,

etc., have been used. People who have one may

use a cutting saw. More

A B C D E F G H I J K L M N O P Q R S T U V W X Y Z

- D

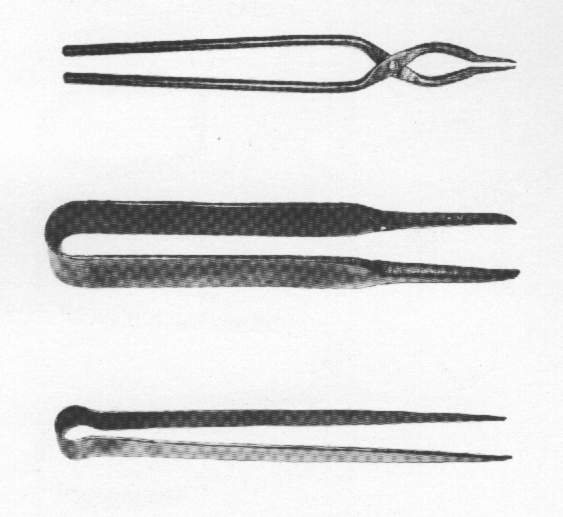

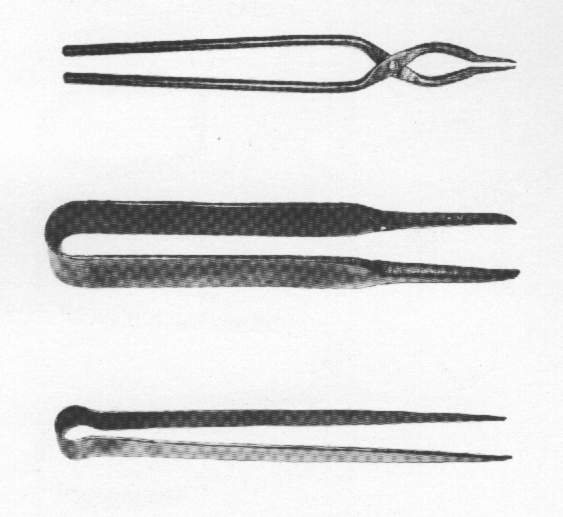

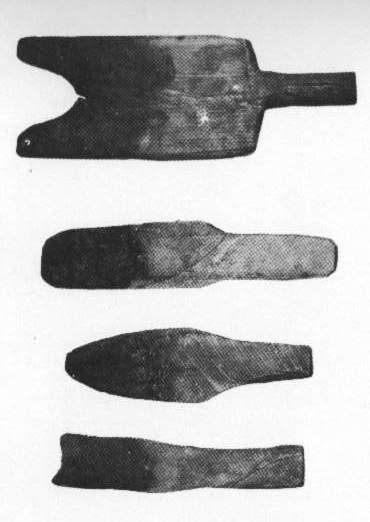

- Diamond Shears

-

Special pliers with a sharp diamond shaped opening for

cutting Hot Glass Bits and, usually, a round

opening at the tip for controlling punties, pulling

glass, etc. Shown at second from left at right. From Steinert $90. See also Shears Special pliers with a sharp diamond shaped opening for

cutting Hot Glass Bits and, usually, a round

opening at the tip for controlling punties, pulling

glass, etc. Shown at second from left at right. From Steinert $90. See also Shears

Sample cheap tools on

the marver - no jacks shown.

- Dip mold

- a one-piece mold open at the top. IGCB

- Dividers

- A tool consisting of two straight arms attached to a pivot. Used

for "walking" off distances on charts or for construction as an alternative

to scaled measurement. Greeks doing math would call them a

compass. Lid Calipers

CalipersImage 2008-05-20

- Dowel, Wood

- Wooden dowels can be used alone or in large tweezer-like

handles. From woodworker supply catalogs in cherry 1/8"

to over an inch. Wood

- Drill, Drill Bit

- A tool for putting round holes in cold glass, the drill

actually being the thing with the motor while the bit is the

variable sized added piece that does the cutting. Covered

in Coldworking including drilling

& cutting glass

- Drop Off Table

- When working glass, it is nice to have a partner, assistant, etc., who

can glove up, take the piece while on the punty and carry it to the

annealer. Some people (me) working alone will take the piece on the

punty, having chilled the join, and place it just above the floor of the

annealer, rap it off (note it is upside down, instead of sitting on its

bottom as it would if a gloved placement were used.) After one has

seen a piece pass between the hands of the assistant and crash on the floor,

one considers a drop off table. This is nothing more than a rimmed

table top, perhaps 18" square, padded with an inch or more of frax blanket,

vermiculite

or fiberglass. It may roll around and store gloves, knock off tools and

other stuff underneath. A metal prop may support the punty if the

table is wood, not metal. The glass is rapped off the punty onto the

table and then carried to the annealer by the gloved blower working alone or

caught above the table by the gloved assistant. 2003-09-05, 2004-07-13

- E

Extruder

- A tool or piece of equipment which applies pressure to a bulk of soft

material to force a relatively thin rod or tube shape out a small opening

shaped to form the rod. Used in industry for food (pasta, filling casings),

plastic, metal (aluminum window frames, etc.) and clay (bricks, pipe),

in art the primary use is clay where it can form the bulk of a shape or

provide a hollow body for further work. Small homemade

extruder Use in glass is limited due to the

high temp and free flow of glass which drops off as blobs. 2011-10-05

- Eye Protection

Every glass worker should have several

levels of eye protection. At a very minimum break

resistant glasses to save the eyes from glass fragments.

Furnace workers, according to tests, should be using at

least a #3 and preferably a #4 welders shade to observe

the furnace and glory hole. I do this with a relatively

low cost ($25) plastic shield on a Jackson 170-S (not the

newer 170SB) head band with Glendale Irex (Blue Diamond)

862 shield stocked in #5. Grainger offers the Sellstrom 39150 Shade 5

face shield complete $23.09, their # 1N785 The full face shield is also

nice in holding off the heat, but I

got the idea from a couple in Michigan who cut off the

lower half of the shield so they don't have to raise it

to blow. Some workers wear welding clip-ons or use a flat

piece of welding glass in a frame at the yoke to look

through. According to tests, UV is not a problem, IR is

too high and protective choices should be made. Many

glass workers use sun glasses or nothing. Every glass worker should have several

levels of eye protection. At a very minimum break

resistant glasses to save the eyes from glass fragments.

Furnace workers, according to tests, should be using at

least a #3 and preferably a #4 welders shade to observe

the furnace and glory hole. I do this with a relatively

low cost ($25) plastic shield on a Jackson 170-S (not the

newer 170SB) head band with Glendale Irex (Blue Diamond)

862 shield stocked in #5. Grainger offers the Sellstrom 39150 Shade 5

face shield complete $23.09, their # 1N785 The full face shield is also

nice in holding off the heat, but I

got the idea from a couple in Michigan who cut off the

lower half of the shield so they don't have to raise it

to blow. Some workers wear welding clip-ons or use a flat

piece of welding glass in a frame at the yoke to look

through. According to tests, UV is not a problem, IR is

too high and protective choices should be made. Many

glass workers use sun glasses or nothing. - F

- Ferro, Ferritti

- The flat plate and short rectangular bars used for

heating cane in a glory hole in Italian work. Plate

carried with a Pastorali

- Files

- Most glassblowers have at least a couple of files around,

often rusty from being too close to the water used with

wood tools. A file can be used to notch the glass of a

heavy neck on a piece to increase chances of it coming

off cleanly. Normally, only the corner of the file is

used on the glass.

- Fingers Hot Fingers

- A form of gimmick for holding small glass objects

including marbles, more often used in torch work

http://www.arrowsprings.com/html/holding_tools.html#hotfingers but

can be made larger. 2008-10-18

- Fire brick

- A brick made to withstand high temperatures, costing more

the higher the temperature, from $1.50 to $25 a brick.

Usually very hard and heavy, a poor insulator. Available

in many shapes. Used for furnaces mostly. See also Fire brick, Insulating. From A.P.Green,

Mexico MO and local offices, National Refractory, see

Refractory in Yellow Pages. [8-1-2000 Recently A.P.Green

was purchased, so name changes are in progress.]

- Fire brick, Insulating

- A very light, soft, easily cut, high temperature material

than can form structural walls for kilns and backup hard

fire brick. It is possible (carefully) to pick up with

the hand an IFB that is at 1000-2000 on one side - I

always use gloves because of other heating effects, just

in case, but I used a brick for a door on a small glory

hole, moving it with a leather gloved hand to get at the

hole.Refractory

- Flame Sensor

- A safety device used to insure that a flame actually

exists when the equipment wants one. Two forms are a

Purple Peeper that looks where the flame to sense the UV

in a flame that does not exist in a hot wall, and a

thermocouple like device that sits in the flame and

detects both the heat and the conductivity of the flame.

Part of the combustion train.

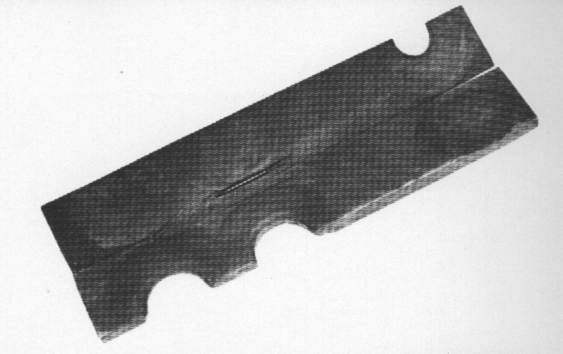

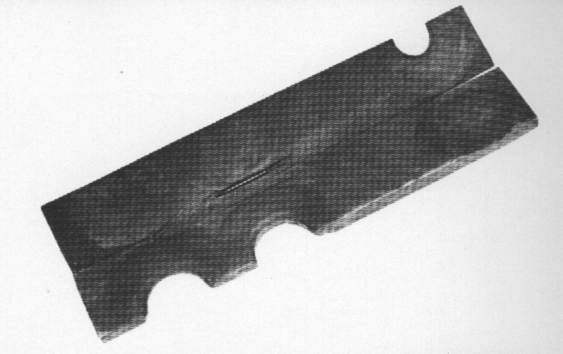

- Footer, Footing Tool

Tool

for shaping the thin flat foot of a goblet. Most commonly

a pair of thin (1/4") fruit wood (cherry) boards

about 3" by 4" (75mm x 100mm) hinged on one

long edge with a slight semicircular dish sanded/cut into

the face of one board along the opposite edge from the

hinge with a notch cut for the stem. The wet tool is

gripped in the palm of the hand and brought up to the hot

glass foot gather and the boards closed around the glass.

The dish forms the upper side of the foot, the flat board

opposite the bottom of the foot. Footer at right, with

three different sized cutouts, from Harvey Littleton's

book. Also made with handles and with graphite pads,

costing about $250 Artco, OLY gls-tech.htm#GOBLETS Tool

for shaping the thin flat foot of a goblet. Most commonly

a pair of thin (1/4") fruit wood (cherry) boards

about 3" by 4" (75mm x 100mm) hinged on one

long edge with a slight semicircular dish sanded/cut into

the face of one board along the opposite edge from the

hinge with a notch cut for the stem. The wet tool is

gripped in the palm of the hand and brought up to the hot

glass foot gather and the boards closed around the glass.

The dish forms the upper side of the foot, the flat board

opposite the bottom of the foot. Footer at right, with

three different sized cutouts, from Harvey Littleton's

book. Also made with handles and with graphite pads,

costing about $250 Artco, OLY gls-tech.htm#GOBLETS- Footsitter Shears

- A term used in a query to MF, something I have not seen

to my best recollection, for a tool doing the same thing

as a Footer (above.) Essemce ? [apparently not,

makes a footer, but not shears form.]

- Fork

- A long handed tool for placing and handling glass in the

annealer and garage, typically with the fork rods covered

with frax or fiberglass to reduce thermal shock. Can be

welded from rebar. CGS sells 7'

forks in 3 styles for $40 each.

- Frit

- Chunks of broken glass the size of raisins to grape nuts;

bigger than powder. Can be bought. For smaller

quantities usually made with crusher if color bar is on

hand.

- Fuming Chamber

- A barrel or box with an exhaust fan and filter, used for

applying chemical effects to the surface of the glass,

when the fumes or dust are potentially poisonous.

- Furnace

- Place for melting glass, built of several kinds of high

temperature (refractory) materials to hold the glass and

hold in the heat without breaking down during the several

months that furnaces usually run. See also Tank,

Pot Furnace, and Refractory.

Furnaces

A B C D E F G H I J K L M N O P Q R S T U V W X Y Z

- G

- Gadget

- A tool for holding the foot of a glass, so a punty does

not have to be used, speeding work. (GGW) a tube with

three spring steel "fingers" that extend. May

also be a special tool for a specific shape, as inside a

production vase for footing (GGNJ) Gimmick

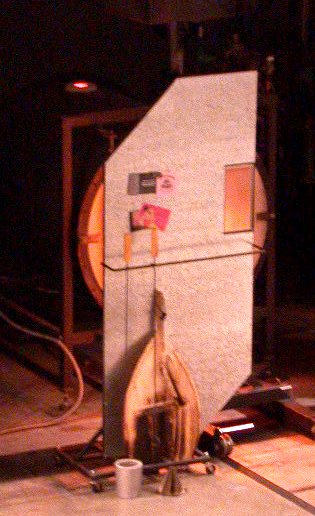

- Garage Glass Garage

-

During the working of glass, it is sometimes useful to

park the glass at or above the annealing temperature (about 900-1000ºF),

until some other work is done. While this can be done in

an annealer, having a smaller space with specially

designed doors can be useful in that it avoids damage to

glass in the annealer and can allow glass still on the

pipe or punty to park in the garage, the pipe extending

through a split door. Notes on my

garage During the working of glass, it is sometimes useful to

park the glass at or above the annealing temperature (about 900-1000ºF),

until some other work is done. While this can be done in

an annealer, having a smaller space with specially

designed doors can be useful in that it avoids damage to

glass in the annealer and can allow glass still on the

pipe or punty to park in the garage, the pipe extending

through a split door. Notes on my

garage

-

-

- Gathering Ball (Rod, Iron)

A hollow ball on the end of a punty rod

used for gathering more glass more quickly than can be

picked up on a punty in two or three gathers. Used for

small casting gathers and for cookies. Can be bought or

welded from small dome caps. The image shows opposite

ends of a 6' long 1/2"square tube with a large dome

cup welded to one end and a ball of small dome caps on

the other end. OLY,

Putsch $25-45 Shells and solid iron balls

available from King Architectural Metals. A hollow ball on the end of a punty rod

used for gathering more glass more quickly than can be

picked up on a punty in two or three gathers. Used for

small casting gathers and for cookies. Can be bought or

welded from small dome caps. The image shows opposite

ends of a 6' long 1/2"square tube with a large dome

cup welded to one end and a ball of small dome caps on

the other end. OLY,

Putsch $25-45 Shells and solid iron balls

available from King Architectural Metals.- Gathering Ring

- A clay ring floated on a large tank furnace. Once the

crud is gathered from the area inside the ring, it

keeps other surface crud from floating in to the space.

Normally not used in crucible furnaces because of the

smaller surface area.

- Gauge, Gage

- A tool, often of fixed shape, for measuring the size of

something, like a cutout of sheet metal the matches the

opening or shape of a production goblet. Also a dial

displaying temp, pressure, etc. Also a measure of

thickness or diameter of metal, as 16 gauge metal, based

on an indirect measure, such as weight per square foot or

a hole in a plate made in 1860 (as wire gages are.) Caliper Dividers

- GFCI

- A Ground Fault Circuit Interrupter is a safety

device on high voltage (120-240 volt ac) circuits,

causing an interrupt when the current out differs from

the current returning by more than a small amount, which

is assumed to be leaking through a human body (but which

may be leaking through water soaked insulation.) Electrical/GFCI

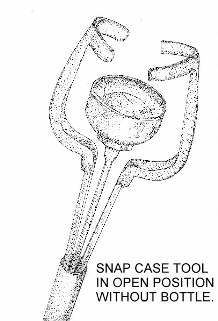

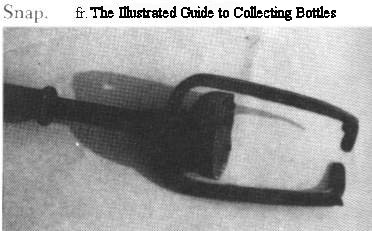

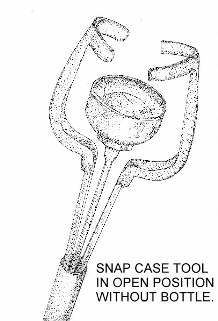

- Gimmick

- A device made to assist in making a piece, usually for holding

glass instead of a hot punty, but may also be a neck

former, lip shaper, etc., that performs a special purpose function. Sabot, Snap 2003-07-01 gripper.htm

Mechanical assistance to a greater or lesser degree may also be used. This

video page shows a

major device for handling a large amount of glass along with several

additional devices including and automatic gaffers bench, rotary kiln and

pneumatic molds. This page shows a large

team handling a mass of glass with a large wheel on the pipe and a pivoting

yoke. 2011-02-16

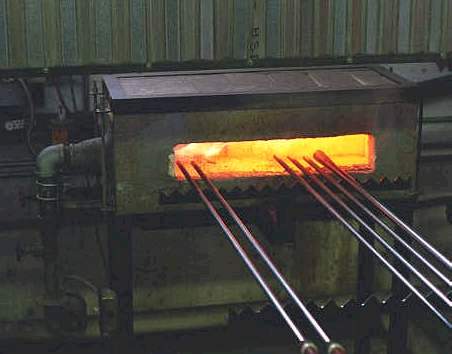

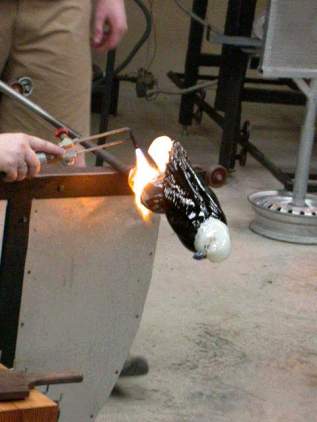

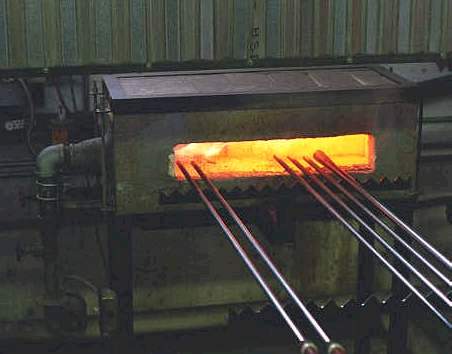

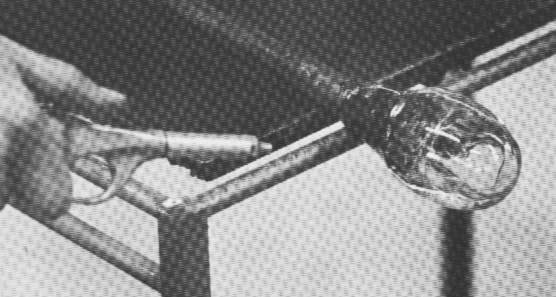

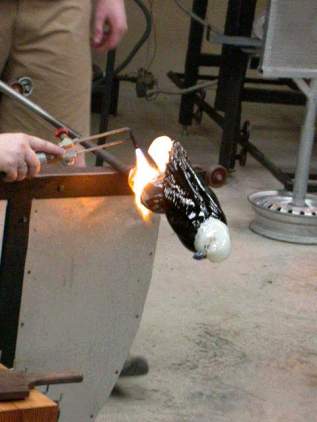

- Glory Hole

- A place for reheating glass. In commercial shops may be

part of a large multi-pot furnace, but in small shops

is usually a separate structure. Usually hotter than

holding temperature of glass furnace and shut off

overnight while furnace is cooking. Usually shop built

from a barrel with castable or fiber or framed with

bricks. Uses more fuel than furnace, shut down when not in use. At

right, small Glory Hole and Yoke in use at Zero Gravity,

encased furnace in background.

Link to image of huge old (1850's) one and

page with several sizes of glory holes.

Also referred to as a reheating chamber because gloryhole is a sexual

reference for some people. 2010-08-13 The Oxford English Dictionary cites a

first use of the term Glory Hole in 1849 "The large goods receive a final

reheating at the mouth of a pot heated by beech-wood, and called the Glory

Hole" Pellatt Curios. Glass Making p.65 "Beech wood is an excellent

firewood, easily split and burning for many hours with bright but calm

flames." Wikipedia Beech 2011-03-18

- Gloves

- Hot shops normally require two kinds of gloves: leather

welding gloves for handling ordinary hot materials and

ceramic fiber/Kevlar for handling hot solid glass in the

600-1000°F. The latter are fairly fragile, should be

preheated to drive off moisture and reduce thermal shock,

and should not be used for tough jobs. They cost about $60

a pair. Leather welding gloves are padded all around and

have long cuffs and only cost about $8-10; when heated

they will get stiff. Leather palmed work gloves may also

be useful for handling cold glass with sharp edges.

Overmitt Old gloves are a common source for tips of grippers (the

fingers) and for

pockets for setting down glass.

Discussion of gloves

2010-08-13

- Grinder

- Cold working equipment for shaping glass roughly before polisher is used. A grinder may be a

flat disk, a vertical wheel or a belt. The first is used

with either grit applied with a water supply or a diamond disk or

pad, while wheels and belts have attached grits. Glass

must always be worked wet, otherwise heat builds up

rapidly and damages the tools and causes cracking in the

glass.

- H

- Hanger, Pipe Hanger

- Used to hold a pipe/punty vertically with the glass

below, to center and cool glass and act as an extra hand.

A V-shaped slot at about head height. Most pipes and

punties are provided with a shaft or hanger collar around

the shaft near the handle. The hanger must have a tapered

shaped opening for various sized pipes and project enough

from the support so a large piece will not hit. Cooling

of paperweights in particular, so the surface will not be

scarred by handling or the annealer, may take five

minutes or more. Homemade from scrap.

- Hanger Ring

- See Hanger

- Hot

- When the eyeballs seem to have a baking sensation. In

Texas at the end of August 2000, when the air temp gets

up to 105°F and no wind is blowing. In glass work when

too much time is spent looking at a 2250°F glory hole

without eye protection. In NOAA weather forecasts, when the temp

hits 99F.

A B C D E F G H I J K L M N O P Q R S T U V W X Y Z

- I

- Iron

- Apparently British usage, Blow Iron, Bit Iron, Punting Iron

The National Glass

Centre - Glossary Steinert uses Bit Iron

for a punty with a small shaft (1/2") and a larger head (3/4" or 1") which

would be convenient for a larger gather when it did not have to be used on

the bench (where the step gets in the way and the small shaft is hard to

turn.) Steinert's are the same length as punties (54"). I have

learned that Finnish glassworkers use a shorter (1m) tool that translates as

spike for bit gathering. 2005-08-19

- J

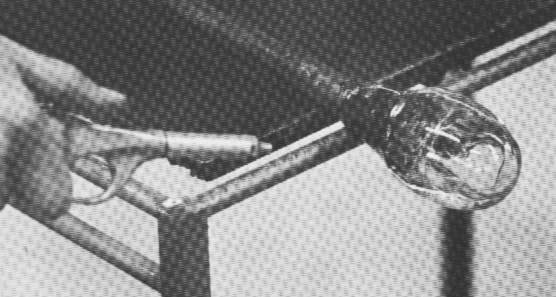

- Jacks

A

hairpin shaped tool that springs open and when closed has

long blades that are parallel about 12-15" long used

for shaping glass. All parts of the tool are used by

skilled glass workers, but the blades get the most use:

closing in the narrow neck of the piece on the pipe and

working the opening of lips. Blades may be nearly knife

edged or rounded. Jacks are also made to hold round (replaceable)

paper or wood "blades" - pacioffis

another image A

hairpin shaped tool that springs open and when closed has

long blades that are parallel about 12-15" long used

for shaping glass. All parts of the tool are used by

skilled glass workers, but the blades get the most use:

closing in the narrow neck of the piece on the pipe and

working the opening of lips. Blades may be nearly knife

edged or rounded. Jacks are also made to hold round (replaceable)

paper or wood "blades" - pacioffis

another image- Jim Moore is considered to make the best in the US, about

$150; OLY; the Italian Dino is

supposed to make the best in the world, $250, buy through

Pilchuck.

- K

- Kanthal (Nickel-Chromium Alloy, 80% Nickel/ 20%

Chromium)

- A higher temp version of nichrome to

be used when a box must be taken up to fusing, casting

and melting temperatures. Beyond Kanthal (a brand name),

silicon carbide rods (and higher voltages) must be used.

- Kiln

- Kiln is an alternate name for oven. A color kiln or

annealing oven may be referred to with the other name. In

the glass studio it is usually electric. While an

annealer usually can't get much above the annealing

temperature (about 1000F), a kiln is usually expected to

be able to get to fusing temps or higher (1500F) The most common forms

resemble chest freezers with the door on top and refrigerators with door on

the front although sliding lids have been used. see also

Lehr, Bell Kiln, Car Kiln

2007-03-20

- Knives, Knife

- Most glass workers have an ugly old knife of some kind, perhaps

"borrowed" from the kitchen. The thin edge and the point are used to reach

in between the punty and the piece to chill small points to start separation

of the piece.

- Knock off table

- Drop off table

- L

- Lathe

-

A lathe is a horizontal motorized turning device. There

are two kinds of lathe involved in glasswork. One is a

large bedded device with two rotating heads used mostly in scientific glass working and

handles tubing, especially large tubing, keeping two

pieces turning and aligned while they are torched for

joining. The other is the more delicate tool holder used for copper wheel

engraving. 2005-12-19 A lathe is a horizontal motorized turning device. There

are two kinds of lathe involved in glasswork. One is a

large bedded device with two rotating heads used mostly in scientific glass working and

handles tubing, especially large tubing, keeping two

pieces turning and aligned while they are torched for

joining. The other is the more delicate tool holder used for copper wheel

engraving. 2005-12-19

- Lehr Leer

- A mechanized annealing oven that is at high heat at one

end and air temp or nearly so at the other. A conveyer

carries glass pieces the length over the time needed for

annealing. Saves the energy of reheating and the wear and

tear of a heat/cool cycle that an oven requires, but only

cost effective in a heavy production shop. Sometimes lehr

is used as just as a name for a cooling oven. In an old

time shop, the pieces are moved by hand from zone to

cooler zone. [2003-10-07 When a person asked by e-mail, I went and

looked for lehr and annealer in the Oxford English Dictionary microprint

edition that I own. Lehr does not appear, while anneal and related

words get a column with references back to the 14th century all related to

heating and burning china, glass, or metal. I am now guessing that

lehr is a jargon term out of the last syllable - as "Put that glass in the

annealer" becomes "In'th lehr"]

- Lid Calipers

- Used for gauging an inside diameter against an outside

diameter, as in a lid that must fit inside or fit outside

of a bottle or jar. Usually X shaped with inwardly

curving tips on one side and slightly outwardly curving

tips on the other, the tip contact points being

the same distance from the pivot. Available from ceramic

suppliers. Calipers Dividers Gauge

- M

- Marver

Metal,

marble or graphite plate, most often steel, used for

rolling glass to a cylinder or cone and chilling the

surface to firm it for blowing. Should be large enough to

roll largest piece over a more than one turn (over 2' for

8" piece) Some marvers are mounted at an angle or

are adjustable to an angle which makes for easier work

when many pieces are to be made with a tapered shape. A

marver may have textured surface (see also Cane Marver . ) Homemade $10-35

from steel scrap yard, or Steinert $75 textured 16"

long. Metal,

marble or graphite plate, most often steel, used for

rolling glass to a cylinder or cone and chilling the

surface to firm it for blowing. Should be large enough to

roll largest piece over a more than one turn (over 2' for

8" piece) Some marvers are mounted at an angle or

are adjustable to an angle which makes for easier work

when many pieces are to be made with a tapered shape. A

marver may have textured surface (see also Cane Marver . ) Homemade $10-35

from steel scrap yard, or Steinert $75 textured 16"

long.

Stephen Powell using marver to pickup colored murrini on

hot glass at '97 GAS Conf. - Mashing Pliers

- Pliers with pads on the end to shape glass, see crimps

- Mold

- A wet or dry form for shaping glass. Dry forms can be

metal, plaster, clay or wood. Wet are wood or metal. Dry forms may

have carbon (from acetylene flame) on the inside.

Molds - Wood & Metal

The most widely used molds are thick cherry wood bowls,

often with handles, used for providing the primary shape

when blowing and for paperweights. Since the bowl size

constantly changes as the wood burns out in use, small

bowls become larger. Other fruit wood may be used. BLOCKS

A variety of other molds are used for blowing into,

usually they are on the floor and the worker stands over

them, then are split to open and remove the glass. OLY CMS

- Mud

- wax mixture used to lubricate steel tools to keep from marking glass,

may include carbon black and various waxes, mostly bees wax and carnuba, a

harder wax.

- Muffle

- a small furnace. IGCB used for

baking painted labels and probably for heating,

preheating and garaging In ceramics, a burned fuel (non-electric)

kiln with indirect heating, therefore a muffle wall to block the flame. MF

A place for heating materials without direct action of the fire.

GL5K 2005-11-28

- Murrini Cutter

- Like a color cutter used for taking slices or chunks

off a rod, but with murrini there is a need for more precision to preserve

the image in the murrini and the losses must be low. Thus devices are

air driven for a snap action with opposing hard shape edges. 2005-03-09

A B C D E F G H I J K L M N O P Q R S T U V W X Y Z

- N

- Newspaper

- Used for shaping glass when formed, wetted and held in

the hand, to replace a marver, mold or block.

Most often made from 4-5 sheets of full

page newspaper, folded first in thirds, then the long ends are tucked into

each other and the corners cut for flexibility and drainage. The result is

flattened and water soaked then drained just before use.

The water keeps the paper from burning and the shape is

controlled by the shape of the hand. Paper marver is used for cylinders

and glass rolled in place, not along it. People who like wood

blocks often hate newspaper while those who use newspaper

think wood is inflexible and expensive. Around Seattle in 2003, people

seem to like very thick pads, not the 4 sheet version. According the

legend, the paper of the New York Times is especially

good at not turning to mush. Wood & Paper

V-Block

- Nichrome (Nickel-Chromium Alloy, 60% Nickel, 16% Chromium (Balance Iron) )

- A wire especially made for heating elements. It

withstands the red hot temperatures without oxidizing to

nothing and without melting. It does, however, get

brittle when heated so it is fairly easy to break a coil.

The size of the wire and the closeness of the coils

determine how hot the element gets and therefore the

heating point of the element. Thin wire has more

resistance and gets hotter for the same current (at higher

voltage.) Coils close together reach a higher temp than

those stretched out. People who work with the wire wind

coils after figuring the total wattage needed and the

length of the space for them to be installed. Eagle used

to make 1000 watt replacement coils, but has stopped and

all the stock is at Elliott's Hardware in Dallas, Texas.

Many people use electric dryer heating elements for

annealers, which is fine, but Nichrome can not be taken

up to fusing and casting temps (1450-1650F) without

sagging and losing it. Kanthal A-1 or

equivalent must be used.

Nichrome can also be used embedded in glass for hangers,

more often fusing than blowing, but it is compatible.

- O

- Optic

- A cylinder, open or closed on the bottom, with even

ridges and groove around the inside, used to produce optical effects

and air stems. Chills glass which can then be twisted,

etc., and pattern remains in glass. Also used for

applying threads of color, which are carefully laid

inside the optic before the glass inserted. Usually

aluminum, almost impossible to home make, Steinert

offers two dozen varieties at $45-100. Almost anything

with an even pattern inside (a spline in a gear) can be

used. An optic for shaping glass only, not holding

stringer, can be made by welding rods or plates to form

an inner cone or other shape. One example of a plate

version can be seen at www.glass.co.nz/glruby.htm

- Ornament Holder, Pocket, Bowl, or Scoop

- When hand making ornaments, the hanging loop can either be wire added

later, like commercial Xmas ornaments or it can be a glass loop. When

making the latter, one cracks off the ornament from the pipe, applies a hot

bit, blobbing it a bit to seal the hold, pulls, cuts, and loops the bit to

touch the blob. Tweezers can be used in forming and shaping the loop

and once it is firm, they can be used to pick the ornament up to place it in

the annealer. So where does the 1100°F ornament sit while the loop is

being applied? Usually in a nest made of a piece of frax fiber in a

bowl the right size. But it may just rest on a drop

off table or be

placed in scoop from which it can be rolled into the annealer.

2003-09-05

- Overmitt

- When Kevlar gloves are used to handle hot glass, they

both get damaged and over heat, prompting the user to peel them off as soon

as possible. One way to avoid/reduce this is to pull on a mitten shape

that adds extra thickness and takes some of the damage, but makes the hands

more into paws. But then, when used, one is usually just clutching

glass at 1100F or so, so fingers are less needed. 2003-09-05

- Oxygen Generator Concentrator

- A device which uses electricity to extract pure

oxygen from water or air. In the former

case, may also supply hydrogen. In the concentrator

form, tanks

of chemicals absorb the nitrogen in the air resulting in a higher

concentration of oxygen. In both cases the quantity is limited by the watts

available and since these are used to reduce the dependence on tanks,

normally they are used for torch working (as well as health needs.)

2009-07-26

- P

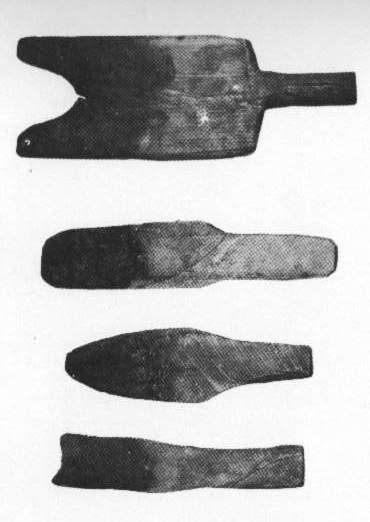

- Paddles

- Boards with handles, fruit wood, usually cherry,

sometimes graphite or metal. Used for flattening glass

and for shielding gaffer's arm. Homemade $5 stock at

hardwood/woodworkers shop. A.R.T.Co $8-14, Paoli $15.

Graphite: Moore $40, Paoli $35. A Tagliol

Paddle is a metal handled, thin metal bladed handle

used in traditional Italian work, especially for cutting

and shaping sculptural work. $55-70. CGS sells 4' handled flat

rectangular paddles for moving items in a garage and also

sell thick cork paddles. Image at right is some well used

paddles shown in Harvey Littleton's

book.

- Pacioffis (Cutting Edge) Parchoffi (Moore, Palmer) Rod

Tongs (Putsch)

- Wooden tipped jacks used to open

pieces without leaving jack marks on the glass. "I

made some a couple of years ago. They are soaking in

water somewhere in the shop." Terry Maxwell. MF

uses cherry wood dowels from woodworking catalog, as

singles, not pairs, various diameters. Image

- Paste Mold

- A metal mold that has been treated with a baked on

compound, special or linseed oil and cork, so that it has a soft finish that

can be soaked in water but is much more durable than wood. 2003-08-20

- Pastorale, Pastoralli, Pastorali

- "An Italian term for the metal tool on which pieces

of cane get preheated in the glory hole or furnace. Don't

have one of these. If I'm going to pick up canes or

inclusions I usually place them on a cane marver and heat

them with a torch. Another alternative is to set the cane

marver on a hot plate and let it heat up." TM Steinert

refers to heating iron cane marvers.

Video showing use

"Confused Boy [says],

This came from Dick Marquis in person. The forked thingy

is the pastoralli and the plate is the fero. He has

forgotten more than I know so I would take his word for

it. Peet "

A flat steel or ceramic plate used for heating bits in

the glory hole, along with a tool to carry the plate and

often a mounted head to allow setting down the plate,

turning it 180° and picking it up to evenly heat. Used

for preheating and partly fusing cane and other elements

for glassblowing. Metal is traditional.

- Pastoralli Carrier - 5" x 8 3/4' x 5' overall

length, $200.00

Pastoralli Carrier 3" x 6"x5' overall length, $165.00

Small Pastoralli plate, 5" x 9", 5 grooves per

inch, $120.00

Large Pastoralli plate, 7" x 13", 5 grooves per

inch, $130.00

PLATE SPINNER, Makes setting hot pastorelli plate down

easier. $200.00, HUB

Correll agrees, spelling the "forky thing"

pastoralli and crosses the fork prongs, so the end is a

rectangle, while calling the plate a ferro and the bars

for holding the glass a ferritti.

Pastorali, 6' $130; Ferro 6"x12" $75, 8" x

18" $95; Ferritti 3 1/2" x 3/8" set of 6 $15.

CGS

- Pallet

- Apparently a

British term for paddle

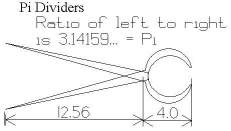

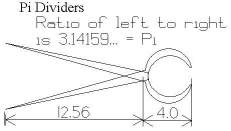

- Pi Dividers

Used to measure a

straight length that will wrap around a circular shape.

Usually made as a pair of curved jaws on one side of a

pivot with straight divider arms on the other. When the

curved jaws touch the outside diameter of the circular

item, the straight arms are 3.1415926... as far apart.

Photo

of Jim Moore's version

Video showing use Calipers

Gauge Used to measure a

straight length that will wrap around a circular shape.

Usually made as a pair of curved jaws on one side of a

pivot with straight divider arms on the other. When the

curved jaws touch the outside diameter of the circular

item, the straight arms are 3.1415926... as far apart.

Photo

of Jim Moore's version

Video showing use Calipers

Gauge- Pick

- Most glass workers have a sharp pointed pick, often bent

at a right angle at one end and straight at the other. It

may be a commercial scribe or be hand made. It is used to

open tiny holes nothing else will get in and to draw

threading in the feathering technique. Beadmakers use a

titanium pick, hard and stands heat.

- Pipe Brush

- This tool can help eliminate the problem of metal flaking

in the head of your blowpipe. Use this tool on a cold

pipe.

- Pipe, blowpipe

- Used for blowing glass, tube with mouth piece on one end, used for picking up

glass on other end, originally of iron/steel, usually today made of low conduction

stainless steel although in 2003 there is a revival of carbon steel

tubes claiming more stiffness and better grip, also cheaper, still with

stainless heads. All pipes flake iron oxide to some degree, SS does it less,

bits can get in glass and burn lips when pipe is raised to blow. Can be as simple as 1/4" IPS

pipe, but usually is a thin wall 5/8"-3/4" tube

with a tapered metal or plastic mouthpiece and a nearly

solid flared pickup end for better glass support.

- While most of the pipe is thin wall

tube, the end that takes the glass is usually turned from

heavy rod or thick wall tube to a flared shape with a small hole (thus being

very thick walled at the end) to provide support for

pieces and to make it easier to form the initial bubble.

The other end is usually a tapered metal or plastic

mouthpiece with moderately thick walls and a small hole. Pipes are

commonly made with wall thickness of 0.062, 0.090 and 0.120 inch. The

most common outer diameter is 0.75", [0.540-1.0"] with 0.75" or 1.0" heads

[.75-1.5"] Commonly 54" long [52-58"] Product Ref.

$20 homemade to $150 Steinert.

Custom length and head size are fairly easy to get. 2003-07-07,

2007-05-09

- Pipe Hanger

- See Hanger

- Pipe Cooler

-

A method of quickly applying water to a pipe which has

gotten too hot to handle often from gathering low glass in a furnace. Can range from a wet rag to a

dedicated spray tube with a foot switch, but the most

common pipe cooler seems to be V shaped box with holes in