| I will start with a history of doors on my equipment that all use the

same method because they

are simple and reflect my choices. Then on to other examples. At right is my ugly old/first furnace door with bad and good choices. The refractory material was brick pieces clamped in a rough angle iron frame clamped by tightening bolts to move the lower edge. The wheels are pulleys with bushing as described below. Below is the first door for my furnace. The door panel itself is insulating castable cast in a pie pan with cast in bolts for mounting. The problems were that insulating castable is not very strong and the door cracked across the mounts. Later versions (below) use a compression ring around the outside of the panel and bolted to a bar across the ring. |

|

|

|

The sketches above and below clarify some of the details mentioned

above and shown in the picture at right. Included are the handle in

the heat shadow (lower left of photo), the steel bar across the back from

the ring around the rim. At the bottom of the rim, barely visible is

the bolt and angle to put the insulating castable into compression. |

|

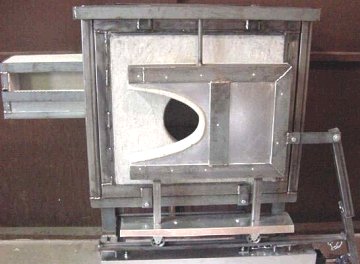

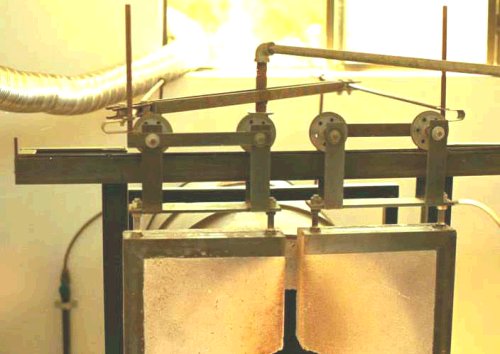

| This is the similar arrangement on a

glory hole door. Because the door is vertical, there is no pivot in

the support. The bottom rail rests on two brackets projecting from the

legs and slides in and out to adjust to the face of the door. The

wheels are on the ends of the support for stability and are mounted to the

front side so the door tends to lean against the front of the hole.

The guard rail that keeps the door from tipping too far away can be made out

as an L near the post left angling down into the picture. The wheels on all my door units are made by buying cast pulley sheaves with 5/8" holes into which I push oilite bronze bushings which are 1/2" inside diameter. I use 1/2" bolts of the right length to have bare shaft to fit in the bearing and two nuts on the 1" of threading, clamping the angle of the bracket between the nuts. If the door was solid castable, not insulating castable, it would be much heavier and if were thicker, it might be so heavy that true grooved caster wheels with ball bearings might be required but they cost several multiples of the pulley and bushing combination. The door was cast by building the frame and laying it face down on plastic, then propping it up about 1/4". The plastic was formed around the metal so the castable flowed to line up with the outer edge, thus forming protection for the steel. A curved piece of Formica formed the curved edge. This was a mistake as a steel should have be welded to form and support the insulating castable which shows a crack in this picture and the upper projection has had to be wired in place. 2006-05-30 |

|

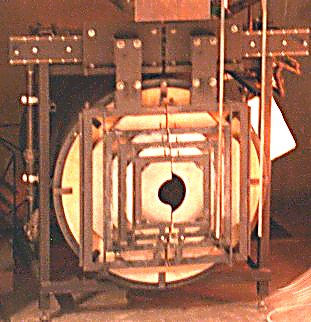

| This door is from Tom Ash and is reduced version from here: http://www.handmade-glass.com/ta_ghole.html The door is pneumatically operated and held snuggly against the flat panel front by track location and guide pin at the top. The hole inside is actually square so the flat panel is being a mask and a lip. The door edge is a parabola. The device to the left is a pipe heater with an opening into the hole that shows in another picture on the page and the bar rests the irons in midair with drip falling away. Insulation guards the strap. The door completely closes the opening so pressure relief for hot gases is provided by the pipe heater opening to prevent/reduce back pressure into the burner head and body. 2008-05-07 |

|

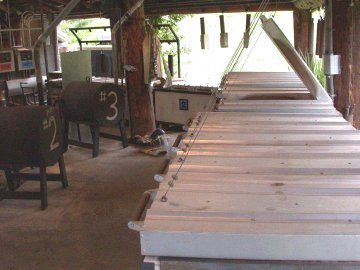

| These two glory holes were photographed at Zero Gravity Glass near Austin Texas in 1998. Other than size, the mechanisms are similar. The doors are simple split doors with a default small hole in the middle. When more space is needed the doors are opened as necessary up to the full size of either glory hole. The picture below shows a detail of mechanism described below which allows the owner to work alone. |

|

| The piping associated with the elbow in the middle top of the picture is the handle extending to the front for working alone. The squarish bar bar below the elbow is connected to smaller rod links. Moving the handle from the right side to the left pushes the doors apart (a double link to move the left door is hidden behind the wheel below one of the links.) The wheels shown are probably pulleys used on the cables for counter balance springs of garage doors which have ball bearings and are available at many hardware stores as door replacement parts.. 2006-05-30 |

|

| This door on a furnace at the old Hickory Street Hot Glass (now disbanded) shows a simple common arrangement with a wheel on a rail at the top. The chief disadvantage is that the wheel lives in the heat rising off the door, probably requiring higher temp materials (not bronze bushings) and graphite lubrication to keep it from corroding and freezing. Advantages include total lack of anything below the door to be messed up if glass drains or drips coming out on second and further gathers. 2006-05-30 |

|

| This sketch shows the top view of a door seen

somewhere forgotten. The advantage is that the mount does not have to

be adjustable or precisely placed to move flush against the furnace face,

thus giving a good heat seal. It does require two sets of aligned

bearings instead of one and the door only works if vertical. 2006-05-30 One furnace door I saw and haven't found a picture yet used a long bent tube that pivoted off the back left corner of the furnace and arched over to hold the door, the whole swinging the side, yet keeping the hot face of the door away from the glass blower. |

|