|

Bottle Cutting with Torch

Cutting glass with a fine tipped torch is old news having been used in the

automated glassware industry for decades and by certain art glass goblet makers.

The problem for most of us is the very small hot flame and turning the bottle.

One choice is discussed below. I was told of a goblet maker who sheared

his by setting them on an old record turntable. I recently received a phone call

from a guy (who promised photos) who said he used the miniature oxy-butane torch

that uses tiny tanks that look like the CO2 cartridges used in seltzer

dispensers and he spin his bottles by tying a yoke on the neck so it hangs

straight and twisting the hanging long cord so it spins for a while. As

with hot wire, the glass may crack on cooling rather than heating. 2009-09-17

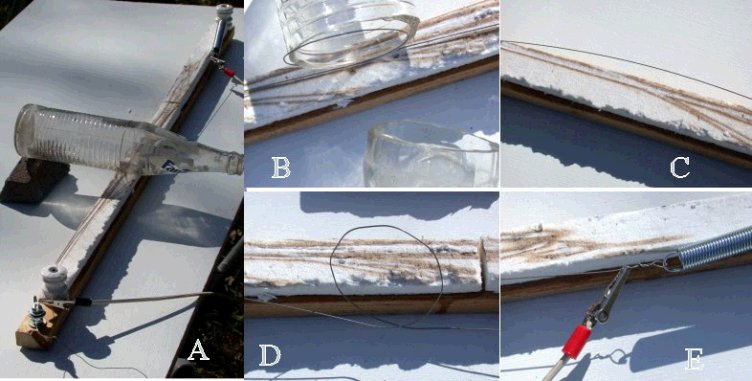

I took various parts I had around and combined them into a rotating bottle

holder and "cut" a couple of bottles with a fine tip welding torch - worked good

with and without scoring. Following comments on CraftWeb about using a

record turntable, a carbide scratcher and a very small torch, I headed for the

garage. I took various parts I had around and combined them into a rotating bottle

holder and "cut" a couple of bottles with a fine tip welding torch - worked good

with and without scoring. Following comments on CraftWeb about using a

record turntable, a carbide scratcher and a very small torch, I headed for the

garage.

I found the Lazy Susan swivel built for

drilling my rod optics and a 3" piece

of 4" conduit welded to a plate with a center hole made for use as a punty mount.

I drilled the swivel in the center to take a bolt through the center of the

holder, with a clearance hole below for access to the nut and counter sinking

the bolt head for a level surface inside the holder. I tapped three holes

at the 1/3 points about 2" up and installed short 1/4" machine screws.

Originally I cut 3 wood blocks to hold the bottle, but they were too thick at

3/4", so I cut a 3" section of 3" PVC and divided it into thirds. I had to

further trim the PVC sections to fit around the bottle. Adjusting the 3

screws centered the bottle on the turntable. The turntable is less than perfect, it turns

but with a bit of a hitch at one point. After running tests, it dawned on

me that I could use a socket on the nut underneath and turn it with an electric

screw driver or drill.

I put the 00 welding top on my Oxy-Acetylene torch and turned the gas pressure down.

Bracing the torch against the table, I started turning the bottle by hand and

pivoted the torch in to play on the bottle. After a few turns, the bottle

snapped on the the line of the torch. I tried a couple of more bottles,

cutting at more than one point with the following results.

- The top of a Coke bottle disintegrated when the turntable hung up briefly

(right)

- A bottle scratched all the way around had a crack that wandered up and

down. (not shown)

- A bottle unscratched produced a lovely even crack while heating.

- A bottle unscratched was heated for longer than average without cracking

but cracked perfectly when the torch was removed. (This also happens with hot

wire sometimes.)

Even the best cuts require smoothing and polishing as described at the

end of Freehand.

|

|

Freehand

All you need is a wooden V, a glass cutter and a 1/4" steel

rod bent at the end with a rubber ball shoved down on it. (below) And then

practice, practice, practice!!!

Most commercial bottle cutters are junk that endures a fad of

heavy advertising on television every few years. Typical price is $29.99 for

something worth about 4 bucks and it still takes practice and skill to work.

I will offer one small exception to this statement as there is now (2003-01) a

unit that looks like it might work better - it has three rubber wheels and a

cutter wheel mounted in the corners of the bottom of an L-shaped platform, the

upright keeping the bottle aligned, so pushing down centers the bottle and

pushes on the cutter one shown here:

bottle cutters - bottle cutting

kit - stained glass supplies - tools

Here are previous notes.

Book: 101 Projects for Bottle Cutters, Fischman, 748.2 F5290

Dallas

Pub.Lib Downtown

Good basic reference for methods, shows about half a dozen

cutting methods/jigs and about the same for breaking, including

ice, fire, nichrome and tapping inside. Projects not reviewed 3/13/95 In

August 2003, I ran into this book again and took a look at the projects.

They are absurd. Most result in something that looks just like a bottle

with a chunk missing. Several call for cutting into the side of a bottle

which isn't really covered in the cutting area. One project is cutting the

bottom off a bottle to make a coaster for a glass. Another involves

cutting the bottom and neck off the center, gluing the bottom to the neck to

make a door handle, glued to a spindle (the middle can be a lamp chimney in

another project.) Sad.

The tools needed are a simple glass cutter used for flat

glass, a trough to hold the bottle, and a rod to tap the score

around the bottle. These are described in the process description

below.

The proper way

to cut bottles is to use a glass cutter (like for window glass,

cheap at the hardware store), placing the bottle in a V-shaped

trough (Two pieces of wood nailed at edge with another to act as

stop for the foot.) Add a brace or hold the edge at the correct

point so the cutter is held fixed (it helps if the wood is wide

enough so the hand can rest on the wood, say 1x4" wood for

ordinary bottles) and the bottle rotated underneath it. Do not go

over the score repeatedly, do it once and don't waste time after

scoring the bottle, it becomes harder if you wait - it "heals". The proper way

to cut bottles is to use a glass cutter (like for window glass,

cheap at the hardware store), placing the bottle in a V-shaped

trough (Two pieces of wood nailed at edge with another to act as

stop for the foot.) Add a brace or hold the edge at the correct

point so the cutter is held fixed (it helps if the wood is wide

enough so the hand can rest on the wood, say 1x4" wood for

ordinary bottles) and the bottle rotated underneath it. Do not go

over the score repeatedly, do it once and don't waste time after

scoring the bottle, it becomes harder if you wait - it "heals".

After

scoring the bottle, a metal rod bent at the end is inserted in

the upright bottle and the glass is tapped, starting a crack,

which can be seen as a silvery surface in the glass, and worked

around the line on the bottle. The rod is most effective if it is

heavy enough (3/16" or 1/4") to have its own momentum

and if a rubber or wooden ball is drilled and mounted on the rod,

then adjusted to rest on the neck so the bent end hits the same

point down in the bottle every time. The bent end should be very

short (especially for cutting wine bottles with small necks) and

the tip should be sharpened to a blunt point for precision. With

a stiff rod, it may be necessary to bend the tip long (1")

to be able to bend it then saw it off short (3/8") and point

it with a file. The middle of the rod may have to be bent to

reach the wall of the bottle in bottles with long narrow necks

and steep shoulders. Check this before scoring the bottle (shown

straight in drawing, would have to bent to get near shoulder. After

scoring the bottle, a metal rod bent at the end is inserted in

the upright bottle and the glass is tapped, starting a crack,

which can be seen as a silvery surface in the glass, and worked

around the line on the bottle. The rod is most effective if it is

heavy enough (3/16" or 1/4") to have its own momentum

and if a rubber or wooden ball is drilled and mounted on the rod,

then adjusted to rest on the neck so the bent end hits the same

point down in the bottle every time. The bent end should be very

short (especially for cutting wine bottles with small necks) and

the tip should be sharpened to a blunt point for precision. With

a stiff rod, it may be necessary to bend the tip long (1")

to be able to bend it then saw it off short (3/8") and point

it with a file. The middle of the rod may have to be bent to

reach the wall of the bottle in bottles with long narrow necks

and steep shoulders. Check this before scoring the bottle (shown

straight in drawing, would have to bent to get near shoulder.

If cutting a large diameter bottle (demijohn, gallon jug) it should be good to

not bend the end to 90° but choose a somewhat more

open angle so the end is at 90° to the glass

at strike so all the weight it just behind the tip. 2008-02-26

Practice with other bottles if trying to cut something in limited

supply. No matter how good you get, some bottles will be lost as

cracks run astray. This was never as easy as the TV ads for the

bottle cutting gimmick (no longer sold) tried to portray.

First sent as MF Reply 11/6/95 8:25 AM

When finished cutting the bottle, the edge is very sharp. The

easiest way to treat the edge is to simply hand grind the edges. This can

be done with the kind of sharpening stones used on pocket knives and chisels,

where each of several grits will cost $5-10. An alternative is a

wooden dowel or a chunk of a broom stick, wrapped with black emery cloth

'sandpaper' where several sizes of grits will cost about $1-2 each. Use

the coarsest grit in each case to knock down the corner of the edges, rounding

it if you wish. Repeat with finer grits, taking out the roughness left

from previous grits. 2003-02-04

This shows an alternative

way of attacking a bottle. The bottle was cut by laying it in the

open gap between two 2x6 boards in an outdoor bench. The hand was

rested on the board in front, holding the cutter and the bottle

was rotated with the other hand. This gives good support for the

hand, but the larger V is needed with a bottle bigger than this,

in my opinion, or a board needs to be set under the hand to raise

it up. When cutting the bottle lengthwise, it is held with one

hand and the cutter used pushing straight down. This picture can

serve as warning because I cut myself rather deeply on the finger.

I had left the neck laying in the groove and was cutting the long

line when the cutter slipped off the glass and I banged my finger

on the very sharp edge of the neck, putting a cut about 1.5"

long perhaps to the bone, but in line with the tendons and

muscles, so a strong bandage replaced several times a day and it

is healing. The damage you see to the bottle was from trying a

medium head torch on the scribe lines to break the glass - not

very successful as breaks occurred in long curves in addition to

following the neck. 2002-02-07 This shows an alternative

way of attacking a bottle. The bottle was cut by laying it in the

open gap between two 2x6 boards in an outdoor bench. The hand was

rested on the board in front, holding the cutter and the bottle

was rotated with the other hand. This gives good support for the

hand, but the larger V is needed with a bottle bigger than this,

in my opinion, or a board needs to be set under the hand to raise

it up. When cutting the bottle lengthwise, it is held with one

hand and the cutter used pushing straight down. This picture can

serve as warning because I cut myself rather deeply on the finger.

I had left the neck laying in the groove and was cutting the long

line when the cutter slipped off the glass and I banged my finger

on the very sharp edge of the neck, putting a cut about 1.5"

long perhaps to the bone, but in line with the tendons and

muscles, so a strong bandage replaced several times a day and it

is healing. The damage you see to the bottle was from trying a

medium head torch on the scribe lines to break the glass - not

very successful as breaks occurred in long curves in addition to

following the neck. 2002-02-07

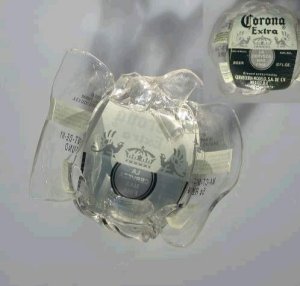

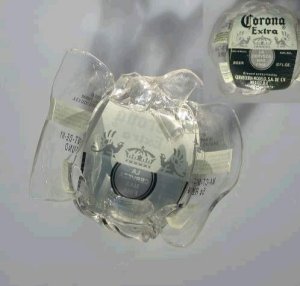

This is a (failed

though interesting) attempt to take apart a

bottle and make a bowl in one step. Originally the bowl was

to be donated to the Empty Bowls so the

label material - which I can't test for lead - was put on the

outside. Obviously the bottle was a Corona beer (inset) and I

chose it because it was 1) Laying on my front yard where it

shouldn't be and 2) it had light thin clear glass. The bottle was

first cut around the neck and tapped on the outside to run the

crack, leaving a piece like the neck in the picture above. Then

the base was cut off around the side and tapped from the inside (more

efficient, less force required.) Then the cylinder of the body

was scored up the sides and tapped inside to break it into front

and back. The back was scored inside (also easier) and divided in

half. The bottle neck was then cut apart into pieces. and the

whole arranged in a bowl mold

for fusing The problem was that while the side pieces sagged and

fused nicely into place, the small pieces from the neck, instead

of filling the gap, fell or folded down into the bowl, leaving an

open gap in the bowl shape. The inset shows the bottom of the

bowl (click to enlarge image) If the bottle was screen printed

hot, the label will normally survive fusing. This one was also

run through the dishwasher to test it. 2002-02-07 This is a (failed

though interesting) attempt to take apart a

bottle and make a bowl in one step. Originally the bowl was

to be donated to the Empty Bowls so the

label material - which I can't test for lead - was put on the

outside. Obviously the bottle was a Corona beer (inset) and I

chose it because it was 1) Laying on my front yard where it

shouldn't be and 2) it had light thin clear glass. The bottle was

first cut around the neck and tapped on the outside to run the

crack, leaving a piece like the neck in the picture above. Then

the base was cut off around the side and tapped from the inside (more

efficient, less force required.) Then the cylinder of the body

was scored up the sides and tapped inside to break it into front

and back. The back was scored inside (also easier) and divided in

half. The bottle neck was then cut apart into pieces. and the

whole arranged in a bowl mold

for fusing The problem was that while the side pieces sagged and

fused nicely into place, the small pieces from the neck, instead

of filling the gap, fell or folded down into the bowl, leaving an

open gap in the bowl shape. The inset shows the bottom of the

bowl (click to enlarge image) If the bottle was screen printed

hot, the label will normally survive fusing. This one was also

run through the dishwasher to test it. 2002-02-07

|

Burning String - I used several soda bottles that I had collected for

fusing and tried several variations. I did not find the results

satisfactory, but they may be in some cases, so read on.2004-12-18

I came across two videos showing the use of acetone (nail polish remover)

that produced better results than shown here. In each case they tie cotton

string on the bottle, remove the string and soak it in a small container

of acetone, replace the string, light it and turn the horizontal bottle on

its long axis while the flame burns with no smoke, then plunge the bottle

into water to snap it. In both videos only a very brief view of the edge

is shown but it appears that both have rough spots. Beer bottle

https://www.youtube.com/watch?v=_A4J7RcdsfM&NR=1&feature=fvwp

Wine

https://www.youtube.com/watch?v=AHxpW60x_KI&NR=1 good captions

2010-03-28

In

a further variation which I have encountered several times just

recently but not tried, again the string is tied tightly around the

bottle and removed, but this time soaked in lighter fluid in a small

bowl before being returned to the bottle and lighted from the bottom

with the bottle horizontal so the flame climbs up and around. When a

crack is heard cold water is dribbled on. Appears to be a cleaner break

and no soot. I have no lighter fluid to test. 2013-12-25

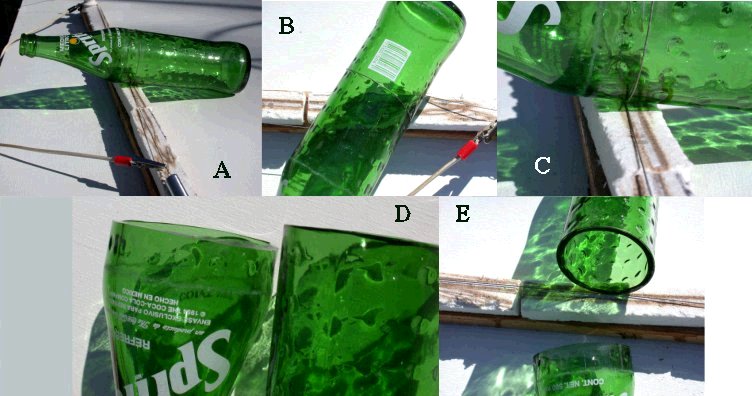

My first tests were on even walled (Sunkist orange soda) bottles, where I

scribed a line, wetted a string in denatured alcohol, tied it in place and lit

it. The alcohol evaporated and burned so quickly as to provide no heat to

the glass. I was also frustrated that the string I knew to be cotton was

too thin and new string I had bought turned out to be nylon or polyester in

spite of not being marked. My first tests were on even walled (Sunkist orange soda) bottles, where I

scribed a line, wetted a string in denatured alcohol, tied it in place and lit

it. The alcohol evaporated and burned so quickly as to provide no heat to

the glass. I was also frustrated that the string I knew to be cotton was

too thin and new string I had bought turned out to be nylon or polyester in

spite of not being marked.

I bought a heavier cotton string at the grocery store. I switched to

kerosene because of its slow evaporation rate. On scribed bottles, with

two wraps of string placed just below and touching the scribed line and the

bottle standing upright, the flame produced a distinctly audible crack at about

the end of burning time. It also produced a black sooty surface.

Unfortunately, the crack followed the scribe halfway around the bottle and then

continued 1/4" higher for the other half. Worse, there was a errant heat

crack that curved about 1/2" below the scribe. So the bottle was cut, but

a lot of grinding would be required to produce an even rim. Several

additional tests were run with essentially the same result. [In the image,

the scribe line is just barely visible against the soot about 1/4" below the

back rim. Note the dip in the rim cut at the front above the lower bulge

of the S. The white visible inside the bottle is the background for the

blue lettering on the other side of the bottle.

Then it occurred to me that the flame would stay along the string if I laid the

bottle on its side, propped on a fire brick so the burn line was out in the air.

This produced less soot and a more controlled flame and with the scribed line,

cracked free, but the crack varied above and below the scribe by 1/8th inch or

more and branch heat cracks showed up.

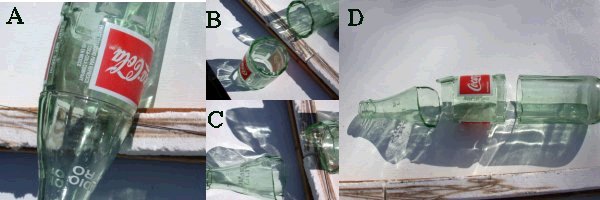

I decided to try some tests with just the burning string, no scribe. This

seemed to give results that were as good (or bad) as previously on the even

walled bottles. I pulled out a couple of old classic Coke bottles.

Here scribing the line is a real problem. Above the label the bottle is

curved, making scribing on the sloping shoulder difficult for me. Below

the label, the bottle is ribbed making for an uneven surface backed by uneven

thickness. Almost any crack around the bottle would improve on what

I have gotten in the past. I decided to try some tests with just the burning string, no scribe. This

seemed to give results that were as good (or bad) as previously on the even

walled bottles. I pulled out a couple of old classic Coke bottles.

Here scribing the line is a real problem. Above the label the bottle is

curved, making scribing on the sloping shoulder difficult for me. Below

the label, the bottle is ribbed making for an uneven surface backed by uneven

thickness. Almost any crack around the bottle would improve on what

I have gotten in the past.

After I wrapped the string soak in kerosene, tied it with an overhand knot,

arranged the ends nicely along the other strands, lit the fuel and stood and

watched. And watched. And watched. The flame went out and the

bottle didn't break. I got a small scoop of water and touched the drip to

the string - ta ta!! Nice crack. It wandered as much as the scribed

bottles without the scribe hassle. I took off the bottom of the same

bottle (around the ribs) and worked a couple of other bottles, getting the same

results.

So, a burning string works to cut a bottle if 1) a medium heavy smooth cotton

string is used; 2) with kerosene, not alcohol; 3) with the bottle on its side;

4) with the ends carefully tucked in; 5) and a large drop of water is applied to

the string as soon as the fire is out;

IF an edge is OK that varies up and down by a good fraction of an inch and will

have to be ground down a bunch to make a drinking glass or goblet AND the loss

of 1 in 3 or 1 in 4 due to branch crack (which keeps running when grinding is

done.) [2005-11-19 After doing the wire snapping below and seeing how even a

small deviation from square can lead to a big point, I think a better choice on

the string would be to use finer string and go around twice with the knot

running under both strings so its width is a smaller proportion of the burning

line.]STRING CUTTING

HI there, love the website, just thought I'd add my way:

My brother and I started cutting old 2 liter ( I think ) glass bottles when we

were around 12 or so, and we didn't use fire, and had no access to batteries.

What we did have were spools of mason line (the kind thaT brick layers use, it's

usually in yellow or day glow pink) from my fathers construction tool bag.

We would tie one end to a hook in a wall, or even a door knob. The string was

played out about 2 feet or so, and the other end was tied to our belt buckle.

making the string wind once around the bottle, we would put some pressure with

our bodies away from the wall, and run the bottle back and forth along the

string, usually getting the string hot enough that it would melt. Immediately

after the string broke, we would dunk the bottle into cold water, and the bottle

would split neatly in half (or wherever the string was).

Possible problems with this technique:

1. you get tired before the string is hot enough

2. the string breaks before adequate heat is generated

3. the point at which the string crosses itself leaves a little dip or rise

in the bottle

4. The string moves along the bottle as you move it back and forth

To address # 2 if only moderate pressure is applied to the bottle, there is

better chance of getting the bottle hot before it breaks. There is also some

brands of mason line that will last longer than others, but I have never figured

out which.

To address #3 if as you move the bottle back and forth you give the bottle a

slight roll, so that the cross point of the string is moving, it will eliminate

the little dip.

To address #4 if I put a layer of tape (masking, scotch, whatever) where the

string will be, the string will cut quite easily through the tape, leaving a

guide for itself, and making it easy to keep in place.

As I said, My brother make many bottles this way, and had none of them shatter.

the only things that can go wrong are that little dip in the cut surface, and

simply not having the bottle break in two, which just means that you have to do

it again.

Anyway, good luck making bottles,

Adrian S. Moreno

San Ysidro, California.

|

Bottle Neck Guitar

Slider I was contacted by someone in the UK to make a

guitar slider from a wine bottle neck and after looking on the Internet

decided the effort in international mailing since a

place in

the UK makes them in different styles. But I wandered to a

discussion

here

from 6-8 years back and thought some of it was worth borrowing.

Guitar sliders require tuning the guitar to an open chord (so it sounds a

chord when strummed) and then a hard object (because using the finger

across all the strings gets painful) is slid along to make other chords.

The Hawaiian steel guitar is played flat with a steel slider, but the

slider can be a piece of steel or brass held edgewise between two fingers

or a tube slipped over a finger. The tube can also be glass, which

is why there is a section here, and the traditional is a piece of wine

bottle neck for the thicker glass.

Note that getting the neck off the bottle, however scored, is easier than

cutting the bottle, since leverage will snap the neck.

Orgodude

posted 12-13-2002 06:43 Edit/Delete Message Reply w/Quote I thought that I

share my slide making experiences. I read through just about everything

that I could find on the topic of bottle cutting. I haven't tried the

special cutting blades or saws.

The only procedure that consistently gave me relatively clean breaks was

the following. Safety glasses and leather gloves are probably not a bad

idea though I've never had any bad experiences with the procedure below.

1. Draw a line around the bottle neck with a magic marker.

2. Score around the line (only once) with the edge of a triangular file .

Using a triangular file allows you to press down firmly with your thumb

directly over the scoring edge of the file thus creating a score of more

consistent depth. It is important to score only once and try to make a

score line of consistent depth otherwise the bottle breaks unevenly. I

practiced on beer bottles first to get the feel of the procedure and then

moved to thicker glass.

3. Heat the score in a candle flame while rotating the bottle. Soot is

deposited where the flame touches the bottle so you know you are hitting

the score line evenly.

4. While hot, rotate the hot score under some cold running water. Usually,

it breaks cleanly. Most times, you can essentially pull the neck off the

bottle. No tapping, smashing, etc. to potentially send glass shards flying

around the room. [Glass shards on the kitchen counter/floor makes my wife

angrier than practicing the same song for hours on end while enjoying the

tone of my newly cut slide.]

5. If neck doesn't break the first time, then dry the bottle, reheat the

score and cool it again. The thicker glass usually required two

heating/cooling operations.

6. Then file and sand smooth.

posted 12-14-2002 15:26 Files come in a variety shapes and sizes (round,

flat, triangular, needle, etc). The triangular file that I am referring to

essentially describes the shape you would see if you looked at a cross

section (cut it in half and sighted down the end). I should add that you

should use one of reasonable size since I broke a smaller one recently.

The reason that I chose this type of file is two fold. One for leverage

and two because my instructor in a laboratory glass blowing short course

demonstrated that this type of file was very efficient for scoring and

breaking glass tubing. For tubing, one just needs to make a score about

one third of the way around the tube to break it cleanly. Interestingly,

if you score a glass tube all the way around the tube it doesn't break

cleanly perhaps due to uneven stresses introduced into the relatively thin

walled glass.

an McWee From: Worcestershire, England

posted 12-02-2003 02:33 After many years of refining the ancient art of

bottleneck making (and it now being a thriving business for us!), all the

above methods listed work for each individual who chooses to make their

very own, personal bottleneck. We found that a lot of the problems

relating to the straight separation of neck from bottle occurred at the

main score-line, opposite to the point of contact with whatever you use to

break the neck off. We found that if you rest the score line directly on

top of a sharp edged, right-angled piece of metal, with the score line

parallel to the top of the angle and resting into the groove, much of the

stress factor on the line was relieved.....and if i knew how to draw a

diagram on here - i'd gladly show you! Hope that all helps, if not - feel

free to contact me off our web-site at

http://www.diamondbottlenecks.com

Spudmurphy

posted 01-22-2004 04:09 Edit/Delete Message Reply w/Quote Who'd have

thought that this would continue over 3 years. An interesting topic.

I used my trusty glass cutter, whose cutting wheel is supplied with

cutting oil - a mixture of 3 in 1 oil and turps. if you dont have such a

beast just dip your cutter in white spirit.

I found it impossible to run a continuous cut all around the neck, but

used a series of small say one inch scores. - on no account double up over

a score, do it once only. Best use a piece of masking tape with a mark

showing your start/finishing point.

Once the perimeter is scored you have to tap around the score with the

other end of the cutter.

Good taps but not so you would expect to "smash"the end off in one go.

Keep tapping all around and a crack will appear - keep tapping and chasing

the crack around and off it comes.

I did 2 bottles in minutes - even took the annoying lip off the cork end

(about 1/4 of an inch) using the same technique.

eskimo

posted 01-22-2004 20:32 A tile wet saw.

I've got one because I am a tile and stone contractor so I thought before

I give this sage advice I'll go out to the garage and try a couple. Worked

6 out of 7 times clean as a whistle. The one that failed was a thin beer

bottle neck that you wouldn't use for slide anyway but the three thickest

ones were the easiest and cleanest. Now some of you are probably saying

that that's all well and good but you don't have a wet saw. Well every

Home Depot does. It's at the end of the tile aisle and it's for weekend

warriors to get their more complex cuts done. The one near me lets all the

homeowner Joe's make their own cuts so that situation would be easy but if

the one near you has the staff do it just slip 'em a 5 spot and off you

go. Or have your wife ask 'em that always works. Either way you might have

to buy $3 worth of tile put some marks on 'em and pretend you need some

cuts done and slip the bottle in at the end. This will work. Home Depot

people do not care about things like this.

Water jets and a fast spinning diamond wheel. It's a beautiful thing.

mark

posted 11-30-2000 19:32 I recently made 2 new slides from wine

bottles. I found 2 wine bottles with real straight necks and small

openings and cut them using a carbide hacksaw blade. Then polished them

with sandpaper--100-400 grit. I held the bottle by laying it on the

kitchen counter on a bath towel, with the towel folded thicker on one end

to support the neck of the bottle. It worked well, but had to rest the

hands several times in the process! The string and ice water method I

tried as well, but this left too jagged a cut requiring too much sanding.

edroperFrom: Seneca Falls, NY

posted 02-09-2004 10:35 I just cut my first bottle neck using the

carbide rod saw, belt sander, sand paper method. I double cut it and it

turned out great. The bottle is from Goose Watch "Finale" white port made

by Swedish Hill Vinyards here in the Finger Lakes. The neck is almost

perfectly straight, thick glass, fits my pinky perfectly, and is a real

nice green/brown color. Oh yeah, I like the tone a whole lot better than

the brass slide I've been using.

clarkythe1st

posted 02-22-2004 18:11 Thought I'd get busy in the workshop and

rustle myself up a few new slides beofre I wasted all those good bottles

at the recycling centre. Found a great Virgin Olive Oil bottle with a

4.5inch straight section. Taped it and cut it with a carbide tipped saw in

a matter of minutes and then spent a good 15 to 20 minutes with a variety

of sanders to get it just perfect. I had a little skip in my step as I

headed back to my guitar. A little too much skip. Caught my foot on a

cable and smash. Oh well, there's plenty more bottles where that one came

from.

|

|

FURTHER COMMENTS:

#: 126130 S5/Glasswork

01-Oct-95 04:18:03 B: #125764-Cutting Glass Bottles Fm: Gerry

Phibbs/CA[Staff] 76556,624 To: Lynn C. Russ 75327,1237 (X)

Hi Lynn..

It's not a difficult thing to do, but as with most things, it can

require some practice to do well.

Bottle glass is typically very soft, and can be cut fairly

easily, but remember that the bottle glass is also of uneven

thickness, and that can create some problems. Also, with many

bottles used for many things, there's a "relief" at the

bottom, or in the bottom, to allow the bottom to break out if too

much pressure is exerted inside the bottle. Be careful around

this little "relief" which will look like a dent in the

glass, it's the weakest point on the bottle.

Peace -Gerry

Even further comments:

Once the bottle has been scored, there have historically been a

number of methods for cracking the glass, most of which are

messy, some dangerous.

Included are wrapping the line with a nichrome wire and heating

the wire (a transformer is required); wrapping the line with

kerosene or lighter fluid soaked string and lighting the string;

filling the bottle up to the line with water and touching the

line with a hot bar or poker; filling it with oil and plunging in

a hot poker. Some of these latter ones may work without scoring

the line, but probably shatter the glass above the line, leaving

pieces of glass to cut people.

MF

Subject: Re: Bottle Cutter? From: zoron@teleport.com (Douglas

Wiggins) Date: Thu, 29 May 1997 15:08:04 GMT

>>Remember the 60's? Looking for way to cut bottles--or at

least neck.

>>Does anyone sell a bottle cutter in the 90's? Or is there

another way to

I have one of those old bottle cutters, and it is a simple

device which involves a simple wheel-type glass scoring tool,

mounted on a jig which allows it to scribe a score around the

circumference of a bottle (it uses wing-nut-fastened adjustments

to let it be set for different diameters of bottles) - putting a

bottle sideways into a partially open drawer and turning it while

holding a glass cutter on it would probably work nearly as well.

Once the bottle is scored, there were a couple of different heavy-gauge

wire tools, bent in such a way as to make a crude hammer at each

end of the wire (bent so that a rounded edge hit the glass), and

a little gadget was attached to the wire to hold it in the neck

of the bottle (there were two such wires, with one being for

small necks and one for large - the large one just used a three-inch-square

piece of fiberboard, held at an angle so that one of the "points"

of the square went down inside the neck), and the wire was then

tapped along the inside of the bottle, moving around it, until it

broke. The idea was to start with a slight tap, and increase the

strength until it started to crack, possibly hunting around the

bottle until a place was found where it would start to crack.

It took a bit of practice, but, once one got the hang of it, it

was possible to cut bottles cleanly nearly every time.

3/14/98 In article <350AF691.757D@digitalexp.com>, Suz writes:

>reading your post about the coke etc bottles. I must say it

came out

>nicely! Now, if I could just figure out a way to cut rings

out of a

>bottle without breaking 3/4 of it! The two rings I have took

me a

>twelve-pack! Is there a better way? btw: i had purchased the

"bottle

>cutter" from Glass Crafters, and it is rather a hit

& miss affair. It's

>plastic, and tends to slide around, and I believe the cutting

wheel is

>rather cheap. Any ideas? -suz-

A. Cut the bottles at least 24 hours after finishing the 12 pack

:-)

B. Open the bottle by cutting as far away from the rings as

possible (see below)

C. Skip using any "bottle cutter" and make your own

much stronger rig.

I cut my bottles (remember the outside of Coke bottles is uneven,

ridged, etc. compared to most other bottles) by first making a

wooden trough to hold the bottle while I turned it. Basically I

chose two pieces of scrap wood, one for the base and another just

wide enough to place the cutting hand in a good position with

respect to the bottle - I think I used 1x3 and screwed it to the

edge of the base.

Also on the base I put a piece of wood scrap about 3/4"

thick just far enough from the upright to keep the bottle in

place and another small piece to position the bottom of the

bottle.

I used a perfectly standard (cheap) hardware store glass cutter.

Because of what I wanted to do, I made my first cut near the base

of the bottle as I recall, although I did a few up on the bulge

at the base of the neck. Turning the bottle in the trough with

one hand, I held the cutter in position with the other to pivot

against the glass.

To run the score, I made my own inside breaker by using 1/4"

steel rod. I bent about an inch of the end to a sharp L in a vise

and then cut off most of the inch until the short leg would fit

inside the neck of the bottle. I then filed the short leg to a

blunt point. Depending on the bottle, I then bent the long part

of the rod to fit the pointer under the shoulder of the bottle if

I needed. As I recall, I couldn't find any wooden or rubber balls

so I roughly shaped a scrap of wood to a ball end, drilled it

undersized and pushed it on the rod to act as a pivot for the

rapper.

Once I scored the line around the bottle, I rapped the crack

around it and took the bottle into two pieces. What happened next

depended on what parts of the design I wanted to use. If

necessary, I ringed the bottle again and rapped it apart. I found

that whether I used the neck rapper from the neck or the ball

rapper on the cutter depended on how the bottle seemed to be most

attackable.

Since you want to make rings, I would suggest taking the bottom

off then scoring above and below your rings and tapping with the

ball through the bigger bottom opening (use gloves or something

to keep from cutting yourself on the sharp bottom edge. If you

felt more comfortable, you could take an abrasive stone to the

newly cut edge.) I usually wanted pieces of the pattern running

up and down the bottle, so I would lay the bottle section down,

reach in through the opened bottom with the cutter (gloves) and

pull the cutter from inside toward me. (Doing one or

more different lines before rapping depending on my mood.) I

would then rap the inside score from the outside of the bottle,

much easier to follow, I found. Of course I ruined a few, but I

kept all the pieces to see what I could do with

short fragments of text, parts of logos, etc. Bottle glass is

uneven in thickness so it tends to produce "creative"

shapes.

Subj: cutting beer bottles

Date: 98-03-15 20:17:40 EST

From: (Stanton, Susie)

To: (MikeFirth)

Hi Mike, gosh thank you for the wonderful post to my question

'is there a better way'. just last night i was having a few beers

with a local carpenter/craftsman and we talked about making a

cradle so i could turn bottles. bobbalou said he thought he had a

pretty good idea of what i want and he will "get right on it".

(course, in island time, that could

be anywhere from 3 months to a year. it's a whole 'nother time

zone here!) so i decided that i am going to try to make what you

have described. but i am having a hard time picturing the thing!

i -was- thinking in terms of having an uprighted end, with a half-circle

cut out, to rest the base of the bottle on, but then the neck

part threw me; is that the scrap 1x3 you meant? also the part for

piece 'just wide enough to place the cutting hand on", is

that so your hand remains firmly set while you turn the bottle?

boogers! i am sorry to ask you so many questions about this!

perhaps i will get down under the house (we are all on 12' stilt/pilings

here) and rummage through my "treasure pile", and see

what i can come up with. i sure do miss that 1970's bottle cutter

they used to make. oh and btw, i also did the "tie cotton

string wetted with kerosene around the base, light, let burn,

plunge into cold water" and it does work! but the wine

bottle cracked a lot up above the break. the bottoms of the wine

bottles have that neat "thumb hole" and i am looking

forward to seeing what it will turn into! i am not an artist at

all, and know it, but i sure do like messing with these things

and seeing what they can turn into. thanks again for that great

informative post!

-suz-___________________________________________________________

________

St. George Island, FL ~ 65 Miles from the nearest WalMart - thank

God!

http://www.digitalexp.com/~users/ses

Make a V of wood - a long trough to lay the bottle down in.

One side should be about the size of the bottle laying on its

side.

The other side should be a bit wider so space is handy to nail

down a scrap of wood.

It should be longer than the bottle, somewhat.

Lay it so the wider side is on the work surface and the narrower

one sticks up.

Lay the bottle in place, letting the neck stick out the end

enough to grab it.

Mark the location of the bottom of the bottle so you can nail a

scrap of wood there to keep it from moving down the trough.

Move a piece of wood into the side of the bottle on the bottom

wood so the

scrap just touches and mark it.

Remove the bottle and nail/screw the two pieces of scrap in place

to align the bottle.

|

I took various parts I had around and combined them into a rotating bottle

holder and "cut" a couple of bottles with a fine tip welding torch - worked good

with and without scoring. Following comments on CraftWeb about using a

record turntable, a carbide scratcher and a very small torch, I headed for the

garage.

I took various parts I had around and combined them into a rotating bottle

holder and "cut" a couple of bottles with a fine tip welding torch - worked good

with and without scoring. Following comments on CraftWeb about using a

record turntable, a carbide scratcher and a very small torch, I headed for the

garage.

This shows an alternative

way of attacking a bottle. The bottle was cut by laying it in the

open gap between two 2x6 boards in an outdoor bench. The hand was

rested on the board in front, holding the cutter and the bottle

was rotated with the other hand. This gives good support for the

hand, but the larger V is needed with a bottle bigger than this,

in my opinion, or a board needs to be set under the hand to raise

it up. When cutting the bottle lengthwise, it is held with one

hand and the cutter used pushing straight down. This picture can

serve as warning because I cut myself rather deeply on the finger.

I had left the neck laying in the groove and was cutting the long

line when the cutter slipped off the glass and I banged my finger

on the very sharp edge of the neck, putting a cut about 1.5"

long perhaps to the bone, but in line with the tendons and

muscles, so a strong bandage replaced several times a day and it

is healing. The damage you see to the bottle was from trying a

medium head torch on the scribe lines to break the glass - not

very successful as breaks occurred in long curves in addition to

following the neck. 2002-02-07

This shows an alternative

way of attacking a bottle. The bottle was cut by laying it in the

open gap between two 2x6 boards in an outdoor bench. The hand was

rested on the board in front, holding the cutter and the bottle

was rotated with the other hand. This gives good support for the

hand, but the larger V is needed with a bottle bigger than this,

in my opinion, or a board needs to be set under the hand to raise

it up. When cutting the bottle lengthwise, it is held with one

hand and the cutter used pushing straight down. This picture can

serve as warning because I cut myself rather deeply on the finger.

I had left the neck laying in the groove and was cutting the long

line when the cutter slipped off the glass and I banged my finger

on the very sharp edge of the neck, putting a cut about 1.5"

long perhaps to the bone, but in line with the tendons and

muscles, so a strong bandage replaced several times a day and it

is healing. The damage you see to the bottle was from trying a

medium head torch on the scribe lines to break the glass - not

very successful as breaks occurred in long curves in addition to

following the neck. 2002-02-07 This is a (failed

though interesting) attempt to

This is a (failed

though interesting) attempt to

I decided to try some tests with just the burning string, no scribe. This

seemed to give results that were as good (or bad) as previously on the even

walled bottles. I pulled out a couple of old classic Coke bottles.

Here scribing the line is a real problem. Above the label the bottle is

curved, making scribing on the sloping shoulder difficult for me. Below

the label, the bottle is ribbed making for an uneven surface backed by uneven

thickness. Almost any crack around the bottle would improve on what

I have gotten in the past.

I decided to try some tests with just the burning string, no scribe. This

seemed to give results that were as good (or bad) as previously on the even

walled bottles. I pulled out a couple of old classic Coke bottles.

Here scribing the line is a real problem. Above the label the bottle is

curved, making scribing on the sloping shoulder difficult for me. Below

the label, the bottle is ribbed making for an uneven surface backed by uneven

thickness. Almost any crack around the bottle would improve on what

I have gotten in the past.